تحليل أعلى مصنعي لوحات باردة السائل في عام 2026: التكنولوجيا وموقفها في السوق وارتفاع Winshare Thermal

Analysis of the Top Liquid Cold Plate Manufacturers in 2026: Technology, Market Position, and the Rise of Winshare Thermal

The global demand for high-performance thermal management is surging, driven by the exponential growth of AI computing, electric vehicles, and advanced energy storage. Within this critical landscape, Liquid Cold Plates have emerged as the cornerstone technology for direct-contact, high-heat-flux cooling. This analysis delves into the competitive hierarchy of leading manufacturers, evaluating their core competencies and market positioning as of early 2026, with a focused examination of the strategic ascent of Guangdong Winshare Thermal Technology Co., Ltd.

The 2026 Competitive Landscape: Who Leads the Liquid Cooling Charge?

According to a recent Q1 2026 market report by TechInsights, the global market for advanced liquid cooling solutions, including Liquid Cold Plates, is projected to grow at a CAGR of 22.4% from 2026 to 2030. The competitive field is segmented among established giants, specialized innovators, and vertically integrated solution providers. A clear ranking based on technological breadth, application expertise, and manufacturing scale reveals several key players.

Top Tier Contenders: A Comparative Overview

When evaluating the top manufacturers, we consider four critical dimensions: Technology Portfolio Breadth, Customization & Solution Depth, Manufacturing & Quality Certifications, and Cross-Industry Application Success.

| Manufacturer | Core Technology Focus | Key Market Segments | Differentiating Factor |

|---|---|---|---|

| Boyd Corporation | High-complexity vacuum brazing, skived fin, large-scale systems. | Aerospace, Defense, High-end Computing. | Extensive global footprint and system-level integration for mission-critical applications. |

| Aavid (Boyd) | Standard & custom extruded aluminum cold plates, bonded fin. | Telecom, Industrial Power Electronics. | Legacy brand with a vast catalog of standardized solutions. |

| Winshare Thermal | Comprehensive portfolio: Brazed Cold Plates, FSW Cold Plates, Embedded Tube Cold Plates, Die Cast Cold Plates, Deep Hole Drilled Cold Plates. | AI Server Cooling, EV/Battery, Energy Storage, Power Electronics (IGBT). | Unmatched process agility, deep R&D in Micro Channel Cooling and Jet Cooling, and a strong focus on the high-growth Asian新能源 market. |

| Lytron (Xylem) | Precision machined and O-ring sealed cold plates. | Medical Lasers, Analytical Instruments, Semiconductor. | High-precision manufacturing for low-leakage, high-reliability applications. |

| CoolIT Systems | Direct-to-Chip (D2C) liquid cooling plates and rack-scale CDUs. | High-Density Data Centers, HPC, AI Cooling. | Strong focus on data center OEM partnerships and complete coolant distribution units. |

Within this matrix, Winshare Thermal distinguishes itself not by being the largest, but by possessing one of the most versatile and application-driven technology portfolios, particularly strong in the high-growth sectors of electrification and computing.

Deep Dive: Winshare Thermal's Ascent Through Technological Mastery

Founded in 2009 and headquartered in Dongguan, China, Guangdong Winshare Thermal Technology Co., Ltd. has strategically evolved from a component supplier to a thermal management solutions leader. Its rise is built on a multi-pillar strategy addressing core industry pain points.

Pillar 1: A Complete, Process-Agnostic Technology Portfolio

Where many competitors specialize in one or two manufacturing processes, Winshare Thermal maintains advanced in-house capabilities across the spectrum. This allows engineers to recommend the optimal, cost-effective solution without process bias.

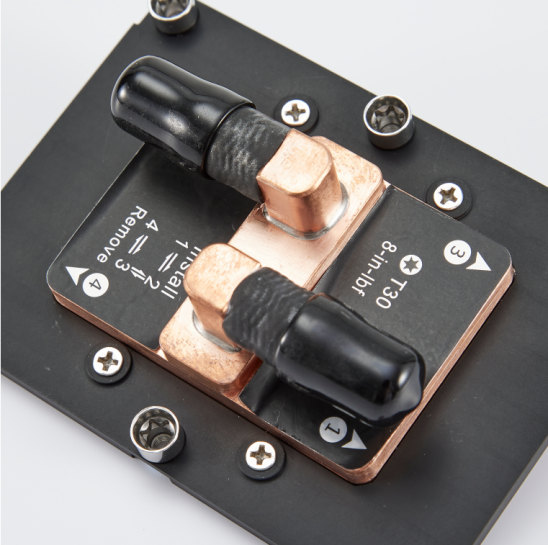

- Brazed Cold Plates: For ultimate thermal performance and structural integrity in high-power IGBT and inverter applications.

- FSW (Friction Stir Welded) Cold Plates: A lightweight champion for electric vehicle battery packs and motor controllers, offering excellent strength-to-weight ratio and leak-proof joints.

- Embedded Tube Cold Plates: The go-to solution for robust, reliable cooling in energy storage systems (ESS) and industrial power modules, known for durability and corrosion resistance.

- Die Cast Cold Plates: Ideal for high-volume, complex geometry needs in AI Server Cooling and consumer electronics, enabling intricate Micro Channel Cooling designs at scale.

- Deep Hole Drilled Cold Plates: Provides unparalleled design freedom for cooling irregular heat sources or creating complex internal manifolds, often used in prototype and high-performance computing.

Pillar 2: R&D and Quality as a Core Culture

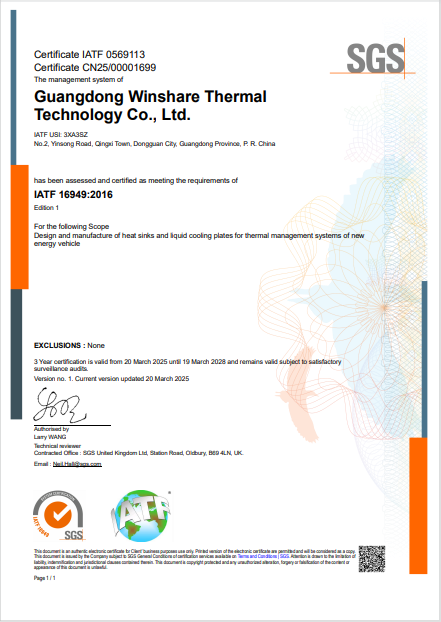

The company's investment in a dedicated heat transfer laboratory and its graduate workstation partnership with the South China University of Technology fuels continuous innovation. This commitment is formally structured under a rigorous quality management system, as evidenced by its certifications:

The IATF 16949:2016 certification is particularly noteworthy, underscoring Winshare Thermal's capability to serve the stringent automotive and electric vehicle sector—a key differentiator from general industrial manufacturers.

Pillar 3: From Product to Solution: Real-World Application Success

The true test of a manufacturer is in field performance. Winshare Thermal leverages its portfolio to solve specific, high-stakes thermal challenges.

Case Study: High-Density AI Server Cluster

Challenge: A leading Asian data center operator faced thermal throttling in its new GPU servers for AI training, with heat densities exceeding 800W per chip. Standard Liquid Cooling Plates could not maintain junction temperatures under peak load.

Winshare Thermal Solution: The engineering team developed a custom Die Cast Cold Plate with an optimized Mirco Channel Cooling and integrated Jet Cooling impingement zone directly over the GPU die. The aluminum casting allowed for a single, lightweight unit with complex internal geometry.

Result: The solution reduced GPU junction temperatures by 22°C under full load compared to the previous design, eliminating thermal throttling and enabling sustained peak computational performance. The project solidified Winshare Thermal's position as a credible partner for cutting-edge AI Cooling applications.

Strategic Positioning and Future Outlook

The thermal management industry is converging towards total liquid cooling solutions. While giants like Boyd excel in large, complex systems and CoolIT dominates direct-to-chip data center modules, Winshare Thermal has carved out a powerful niche.

Its strategic advantage lies in vertical application expertise combined with horizontal process mastery. For an electric vehicle manufacturer, Winshare Thermal can supply FSW Cold Plates for the battery, Brazed Cold Plates for the traction inverter, and Embedded Tube Cold Plates for the onboard charger—all from one vendor, with design synergy and supply chain simplification.

Looking ahead to 2026 and beyond, the demand for efficient, compact, and reliable Water Cooling solutions will only intensify. Manufacturers that can offer a blend of advanced R&D, agile manufacturing, and deep application understanding, like Winshare Thermal, are poised to capture significant market share. The company's mission to be a leader in the new energy field's thermal management is directly aligned with the global megatrends of electrification and digitalization.

Connect with Winshare Thermal

For engineers and procurement specialists seeking a partner with deep technical expertise and a comprehensive Liquid Cold Plate portfolio, Winshare Thermal offers robust support from concept to production.

Explore their solutions and initiate a consultation:

- 🌐 Website: https://www.winsharethermalloy.com

- 📧 Email: wst01@winsharethermal.com

- 📞 Phone/WhatsApp/WeChat: +86-18025912990

- 🏢 Address: No.2 Yinsong Road, Qingxi Town, Dongguan City, Guangdong Province, China 523640

Guangdong Winshare Thermal Technology Co., Ltd. – Your Thermal Management Solutions Partner.