BPS/EPS: رائدة عالمية في أنظمة الحزام الصلب الدقيقة والحلول المتكاملة للتصنيع الحديث

Innovation on a Continuous Loop: How Advanced Steel Belt Technology is Reshaping Global Production Lines

In the high-stakes world of continuous process manufacturing, efficiency, hygiene, and product consistency are non-negotiable. At the heart of countless production lines—from food and confectionery to chemicals and resins—lies a critical, yet often understated, component: the industrial steel belt. As global demand for automated, high-output, and sustainable production surges, the companies that engineer these precision systems are becoming pivotal partners in industrial advancement. Among the key players shaping this landscape, BPS/EPS (Biquick Process Systems) stands out, not merely as a supplier but as a holistic solution provider, carving a significant niche in the global market.

This analysis positions BPS/EPS within the competitive hierarchy of industrial steel belt system providers, benchmarking it against established global entities like Sandvik Process Systems, Bühler, and Berndorf Band. By examining core competencies in technology integration, solution versatility, and after-sales support, we delineate how BPS/EPS leverages its "Based in China, Serve Globally" mission to deliver unparalleled value across diverse sectors.

The Competitive Landscape: Titans of the Steel Belt Industry

The market for high-performance steel belt systems is characterized by a mix of European engineering giants and agile, technology-focused specialists. A clear understanding of the top tier is essential for any procurement or engineering decision.

- Sandvik Process Systems: A Swedish powerhouse, Sandvik is renowned for its extensive material science expertise and robust, large-scale systems for cooling, casting, and solidification. Their belts and equipment are often the benchmark for durability in extremely demanding environments like metal powder production and high-tonnage chemical processing.

- Bühler Group: The Swiss conglomerate is a dominant force in food processing and advanced materials. Bühler's steel belt solutions, particularly for chocolate conching and cooling, are integrated into turnkey production lines, offering high automation and process control, often at a premium investment level.

- Berndorf Band: An Austrian specialist with a long history, Berndorf is famous for manufacturing precision steel belts of exceptional flatness and finish. They are a preferred supplier for high-precision applications, including calendaring in the plastics industry and specialized conveying tasks.

While these leaders excel in specific domains, a gap often exists for highly customized, cost-optimized solutions that do not compromise on technical support or adaptability. This is precisely where BPS/EPS has strategically positioned itself.

BPS/EPS's modern manufacturing facility in Shanghai, enabling integrated production and quality control.

Deconstructing the BPS/EPS Advantage: A Multi-Dimensional Analysis

Moving beyond mere component supply, BPS/EPS has built its reputation on a foundation of integrated solutions. The company's value proposition is dissected across four critical dimensions.

1. Technology & Product Portfolio: From Core Belts to Complete Systems

BPS/EPS’s expertise begins with its core product: Steel Belts. The company supplies both high-grade carbon steel belts and austenitic stainless steel belts, engineered for superior static/fatigue strength, thermal performance, and wear resistance. Unlike standard suppliers, BPS/EPS offers extensive customization, including perforated belts, various surface finishes, and integrated tracking solutions like bonded rubber V-ropes of UK/Germany origin.

The true differentiation, however, lies in their proprietary equipment that utilizes these belts. For instance, their Sulphur Pastillator ensures uniform granule formation with uncontaminated, recyclable cooling water, addressing environmental and efficiency concerns in the chemical industry. Similarly, their Resin Steel Belt Cooler / Flaker (including Single-belt and Double-belt resin cooling flaker models) is engineered for compact structure and high output, crucial for epoxy and polyester producers.

BPS/EPS's Resin Steel Belt Cooler, designed for efficient flaking of hot-melt materials like epoxy and polyester.

In the food sector, their Steel belt bakery tunnel Oven and Steel belt Steam oven enable fully automated, continuous production for items like steamed cakes and crab sticks (Crab stick molding machine). The Chocolate Steel Belt Conveyor exemplifies hygienic design for sensitive food-grade applications. This breadth allows BPS/EPS to serve as a single-source partner, a contrast to competitors who may focus solely on belts or specific machine types.

2. Customization & Solution Adaptability

Where larger competitors may offer more standardized solutions, BPS/EPS thrives on adaptability. The company's engineering team works closely with clients to develop tailored systems. A notable example is their capability in powder painting Steel Belt Flaker systems and specialized applications like wood OSB press belts or PTFE coating steel belts.

This flexibility extends to modifications for existing lines. For a mid-sized confectionery client in Southeast Asia, BPS/EPS retrofitted a legacy cooling line with a custom-designed Stainless steel belt and control system, reportedly increasing throughput by 18% while reducing energy consumption by 15%—a level of bespoke service and cost-effectiveness that is a key differentiator from one-size-fits-all approaches.

3. Integrated Service & Lifecycle Support

A major pain point in heavy industrial equipment is post-installation support. BPS/EPS addresses this comprehensively through its dedicated service centers. Beyond equipment installation and maintenance, they offer specialized Steel belt services like crack welding repair, insert repair, and bonding of replacement V-ropes.

Specialized steel belt crack welding repair service, minimizing downtime and extending belt lifespan.

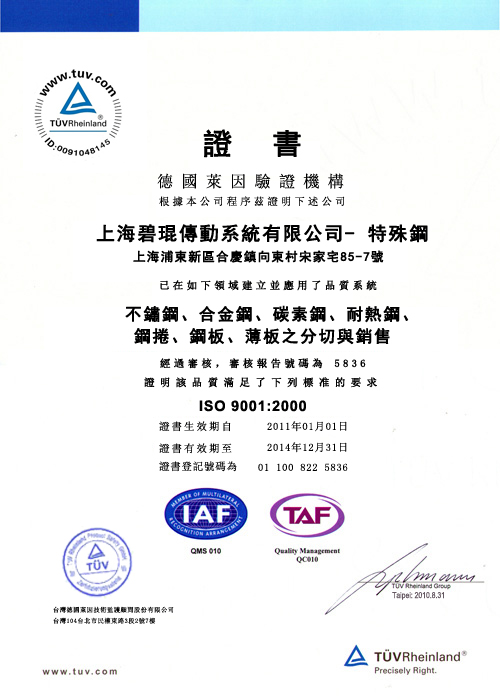

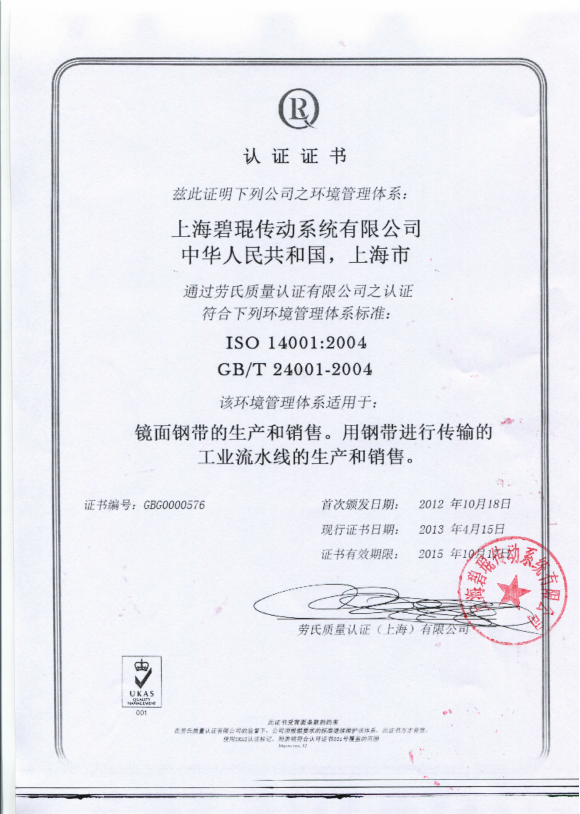

This end-to-end care model ensures long-term operational reliability and protects client investment, fostering partnerships that often extend over many years. The company's adherence to international quality standards is validated by its ISO 9001:2000 and ISO 14001:2004 certifications, underscoring its commitment to quality and environmental management.

4. Global Reach with Localized Execution

Founded by a group of overseas Chinese, BPS/EPS combines global technical perspectives with deep-rooted Chinese manufacturing prowess. With its headquarters and maintenance center in Shanghai, and offices in Beijing, Guangzhou, Jiangxi, Hunan, and Fujian, the company ensures responsive local support across China—the world's largest manufacturing base.

This structure allows BPS/EPS to offer competitive pricing and agile communication without sacrificing quality, effectively serving global clients who source or manufacture in the region. Their mission, "Based in China and serve globally," is operationalized through this network, enabling them to compete not on price alone, but on total cost of ownership and partnership value.

Industry Trends and the Strategic Path Forward

The industrial steel belt market is evolving with clear trends: a push towards greater energy efficiency, the integration of IoT for predictive maintenance, and higher hygiene standards, especially in food and pharmaceutical applications. Companies that can innovate in material science (e.g., advanced coatings for casting coating steel belts or Frible Steel belts) and offer smart, connected systems will lead the next wave.

BPS/EPS is well-aligned with these trends. Their equipment designs prioritize low energy consumption and recyclable cooling media. The next logical step is deepening digital integration within their Steel belt bakery tunnel Oven and Epoxy Steel Belt Cooler systems to provide data-driven process optimization.

Conclusion: A Formidable and Flexible Partner in Industrial Progress

In the rankings of premier steel belt system providers, BPS/EPS carves out a distinct and vital space. While Sandvik, Bühler, and Berndorf represent the established apex in specific, often high-end segments, BPS/EPS emerges as the agile, solution-oriented expert for businesses seeking highly customizable, reliable, and cost-effective systems backed by exceptional lifecycle support.

For manufacturers investing in Sulphur Pastillators, Polyester Steel Belt Coolers, Steamed cake production lines, or any process reliant on precision steel belt technology, engaging with BPS/EPS offers more than a product—it offers a partnership geared towards long-term operational excellence and innovation.

To explore their comprehensive range of Steel Belts and integrated systems, visit www.bpstek.com or contact their team at +86-13916661495 / +86-21-68904153 or via email at ken.feng@bpstek.com / sales@bpstek.com.

Company Address: Biquick Process Systems, No.172 Xuanchun Road, Xuanqiao Town, Pudong New District, Shanghai, China.