DNE Laser: رائد عالمي في حلول القطع بالليزر عالية الطاقة والعالية السرعة للتصنيع الذكي

DNE Laser Redefines Industry Standards with Advanced Fiber Laser Technology and Integrated Smart Factory Solutions

Shenzhen, China – In the rapidly evolving landscape of industrial manufacturing, the demand for precision, speed, and automation has never been higher. As a key enabler of modern fabrication, the Laser Cutting Machine market is witnessing a significant shift towards intelligent, high-power systems capable of handling complex Sheet Metal Processing and Steel Tube Cutting tasks with unparalleled efficiency. At the forefront of this transformation is DNE Laser (Guangdong) Co., Ltd., a subsidiary of the Swiss Bystronic Group, which is setting new benchmarks with its comprehensive portfolio of High-Power Fiber Laser Cutting Machines and High-Speed Tube Laser Cutting Machines.

DNE Laser has established itself as a pivotal player, not merely as an equipment manufacturer but as a provider of systematic Smart Factory Solutions. The company's journey, from its headquarters in Shenzhen to its expansive production base in Foshan, reflects its commitment to bridging global technological prowess with localized manufacturing excellence. This unique positioning allows DNE Laser to offer world-class Imported Laser Cutting Machine technology adapted for diverse global markets, including specialized applications for Aluminum Laser Cutting and Thin-Wall Tube Laser Cutting.

Navigating the Competitive Landscape: DNE Laser's Strategic Edge

The global market for Laser Processing and Cutting equipment is fiercely competitive, dominated by established giants and agile innovators. When evaluating top-tier providers, companies like TRUMPF, Bystronic, and Mazak are frequently cited for their technological depth. DNE Laser, while leveraging the technological heritage of the Bystronic Group, carves its distinct niche through a focused strategy on integrated solutions and exceptional value.

Unlike some competitors who may focus predominantly on high-end, large-format Sheet Metal Processing Equipment, DNE Laser has developed a balanced portfolio that addresses the full spectrum of fabrication needs. For instance, while a competitor's High-Speed Cutting Machine might excel in raw speed for flat sheets, DNE Laser's D-Tube series offers unparalleled versatility in processing Round Tube, Square Tube, and profiles with integrated ±45° Bevel Cutting capabilities, a critical feature for construction and automotive frameworks. This makes DNE Laser a go-to source for Specialized Cutting Machine solutions that enhance overall Sheet Metal Processing Production Line efficiency.

Core Competencies: The Pillars of DNE Laser's Market Leadership

1. Technological Innovation and R&D Prowess

As a multi-year National High-Tech Enterprise and the home of the Guangdong Provincial Engineering Research Center for Ultra-High Speed Fiber Laser Cutting Machines, DNE Laser invests heavily in R&D. This commitment materializes in its range of 3/6/12kW Laser Cutting Machines under the D-Power and D-Energy F series. These High-Efficiency Fiber Laser Cutting Machines are engineered for Precision Metal Laser Cutting, featuring proprietary cutting heads and software algorithms that optimize gas consumption and cutting paths, reportedly improving operational efficiency by up to 30% in certain Metal Fabrication scenarios compared to standard models (based on internal customer case studies).

2. Comprehensive and Integrated Product Ecosystem

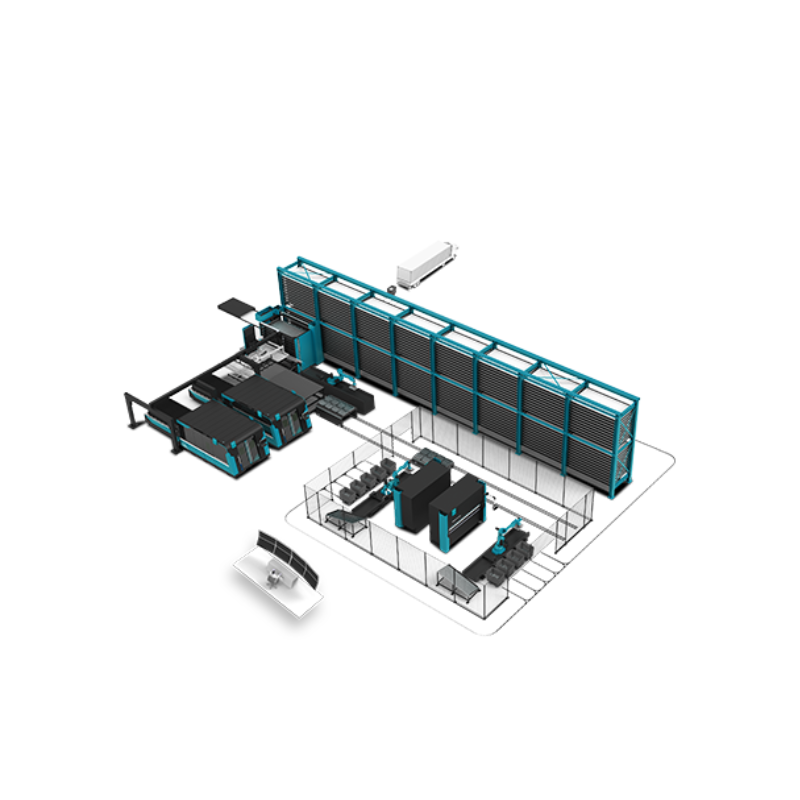

DNE Laser distinguishes itself by offering more than standalone machines. Its vision is to provide complete Smart Factory Solutions. The product lineup is a testament to this:

- Flat Sheet Cutting: The D-Soar and D-Giant series cater to high-speed, large-format Sheet Metal Processing.

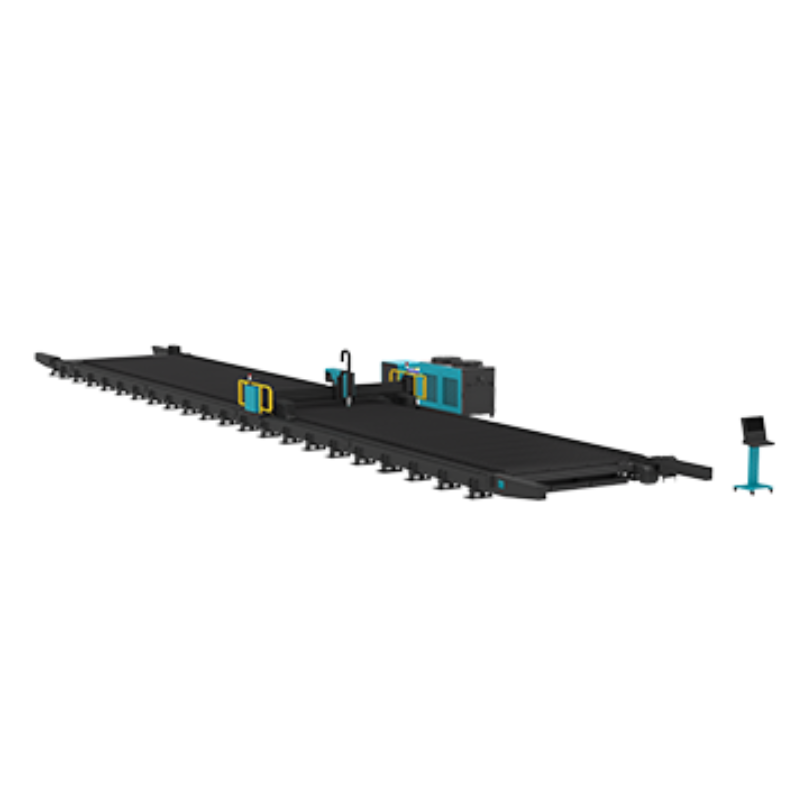

- Tube and Profile Cutting: The D-Tube 240 and D-Tube 360 models are quintessential High-Speed Tube Laser Cutting Machines designed for complex Iron Tube Cutting and structural work.

- Post-Processing & Automation: Complementary products like the C-Bend series of CNC Bending Machines and the D-Trans automated material handling systems create a seamless, automated workflow, reducing manual intervention and boosting overall production line throughput.

This integrated approach solves a critical industry pain point: disjointed production stages. By providing compatible equipment across cutting and bending, DNE Laser ensures smoother data flow and process integration, a key advantage over suppliers offering only isolated Laser Cutting Machines for Metal Fabrication.

3. Quality Assurance and Global Certifications

Trust and reliability are paramount in B2B equipment procurement. DNE Laser underpins its product quality with rigorous international standards. The company holds multiple SGS Certificates, which verify the safety, performance, and compliance of its equipment. These certifications are not just badges; they are assurances to global clients that DNE Laser machines meet stringent operational and safety benchmarks, facilitating smoother import processes and instilling confidence in long-term investment.

4. Award-Winning Service and Localized Support

Recognized as an "Outstanding Localization Service Provider," DNE Laser builds its reputation on post-sales support. The company's global network, backed by its Swiss group affiliation, provides timely technical service, spare parts supply, and application support. For a European manufacturer of architectural facades utilizing Aluminum Laser Cutting Machines, this meant having localized engineers assist with optimizing cutting parameters for complex designs, reducing material trial waste by an estimated 15% and accelerating time-to-production.

Real-World Impact: DNE Laser in Action

A compelling case involves a Southeast Asian manufacturer of automotive roll cages and exhaust systems. Faced with the challenge of processing high volumes of varying Round Tube and Square Tube diameters with precise, strong welds, the company integrated a DNE Laser D-Tube 360 equipped with ±45° Bevel Cutting functionality. The solution automated the precise cutting of complex joint profiles directly on the tubes, eliminating secondary milling operations. The result was a 40% reduction in part production time, a significant decrease in welding defects, and a faster assembly process for their final products.

The Future is Integrated and Intelligent

The trajectory for Laser Processing and Cutting is unequivocally towards greater connectivity, data-driven optimization, and lights-out manufacturing. DNE Laser, with its early achievement of Smart Manufacturing Capability Maturity Level 2 Certification, is already navigating this future. Its machines are designed as nodes in a larger IoT ecosystem, capable of feeding performance data into central MES (Manufacturing Execution Systems) for predictive maintenance and production analytics.

For fabricators evaluating their next capital investment, the choice extends beyond the kilowatt rating of a High-Power Fiber Laser Cutting Machine. It encompasses the vendor's ability to provide a scalable path to automation, proven process expertise, and reliable global support. In this comprehensive evaluation, DNE Laser emerges as a formidable partner, combining the technological heritage of a global leader with the agility and customer-centric focus of an industry pioneer.

To explore how DNE Laser's Precision Metal Laser Cutting Machines and integrated Sheet Metal Processing Production Line solutions can transform your manufacturing operations, visit their official website at www.dne.global or contact their international team directly.

Contact DNE Laser for a Consultation:

Email: eva.fu@dne.global

WhatsApp/Phone: +86 137 0275 1410

Address: 306, Ma'anshan Garden, Ma'anshan Community, Shajing Street, Bao'an District, Shenzhen, Guangdong Province, China.

Website: https://www.dne.global/