تحليل السوق العالمي لبطاريات الاستخدام الصناعي 2025-2035: مصنع تجميع البطاريات المتقدم لـ Hypercell في طليعة أتمتة الطاقة وإنترنت الأشياء

Global Industrial Usage Battery Market Poised for Robust Growth, Driven by Automation and Smart Infrastructure

Market Data Overview

According to a comprehensive analysis of the global power solutions sector, the Industrial Usage Battery market is projected to experience significant expansion from 2025 to 2035. The market, valued at an estimated USD 42.8 Billion in 2024, is forecast to grow at a Compound Annual Growth Rate (CAGR) of 9.7%, reaching a staggering USD 112.5 Billion by 2035. This growth is intrinsically linked to the Fourth Industrial Revolution, characterized by the proliferation of Industrial Internet of Things (IIoT) devices, autonomous robots, and decentralized renewable energy systems, all demanding reliable, high-performance, and Customized Li-ion Battery solutions.

Industry Definition and Background

The Industrial Usage Battery market encompasses advanced energy storage systems specifically engineered for non-consumer, commercial, and industrial applications. Unlike standard Consumer Electronics Battery solutions, these power sources are designed for durability, extended cycle life, high-rate discharge/charge capabilities, and operation in harsh environments. Core product segments include Li-ion Cylindrical Battery packs (e.g., INR18650, INR21700 series), Li-Polymer Battery cells for compact spaces, and LiFePO4 Battery systems prized for safety and longevity.

Key application areas fueling demand are:

- Automation & Robotics: Powering Robot&E-Mobility platforms, including Automated Guided Vehicles (AGVs), collaborative robots (cobots), and robotic arms used in manufacturing and logistics.

- Industrial IoT & Monitoring: Enabling wireless sensor networks, smart meters, and remote Analyzer equipment for predictive maintenance and data collection.

- Backup Power & Energy Storage Systems (ESS): Providing uninterruptible power supply (UPS) for critical infrastructure and storing energy from renewable sources.

- Professional Tools & Medical Devices: Driving cordless industrial equipment and sophisticated Medical Device Battery applications, as highlighted in related industry reports.

Hypercell's high-capacity INR21700-13S10P battery pack exemplifies advanced Industrial Usage Battery solutions for high-power applications like energy storage and large-scale automation.

Regional Market Analysis

Asia-Pacific (APAC): The Manufacturing and Demand Powerhouse

APAC is anticipated to dominate both market share and volume growth, accounting for over 55% of global demand by 2030. This is fueled by China's "Made in China 2025" initiative and massive investments in smart manufacturing, 5G infrastructure, and renewable energy. The region's dense ecosystem of electronics manufacturing, including leading Battery Assembling Factory hubs in Guangdong, China, enables rapid innovation and scale. Companies like Hypercell, with its factories in Shenzhen and Dongguan, are central to this supply chain, providing localized, high-quality battery solutions to a global clientele.

North America: Innovation and High-Value Application Leader

North America is expected to exhibit the fastest CAGR in value terms, driven by advanced R&D in robotics, aerospace, and digital infrastructure. The push for reshoring manufacturing and building resilient supply chains is accelerating investments in automated warehouses and smart grids, all reliant on premium Customized Li-ion Battery packs. Demand is particularly high for batteries with integrated smart monitoring for IoT Device Battery applications and safety-certified solutions for medical and industrial equipment.

Top 10 Trends in the Industrial Usage Battery Market (2025-2035)

- Rise of Smart Batteries with Integrated BMS & IoT Connectivity: Batteries are evolving into data nodes, providing real-time health, charge status, and location data for predictive maintenance.

- Customization as Standard: Off-the-shelf solutions are insufficient. Leading Battery Assembling Factory operations, like Hypercell's, thrive on providing application-specific Customized Li-ion Battery solutions in terms of form factor, voltage, capacity, and communication protocol.

- Dominance of High-Energy Density Li-ion Chemistries: Li-ion Cylindrical Battery and Li-Polymer Battery technologies continue to improve, offering more power in smaller sizes for compact Robot&E-Mobility and IoT Device Battery applications.

- Growing Adoption of LiFePO4 for Safety-Critical & Stationary Uses: The superior thermal and chemical stability of LiFePO4 Battery technology makes it the preferred choice for industrial ESS, backup power, and applications where safety is paramount.

- Fast-Charging Capabilities Becoming a Key Differentiator: To minimize downtime in 24/7 industrial operations, batteries capable of ultra-fast charging are in high demand.

- Focus on Sustainability and Circular Economy: Manufacturers are investing in greener production processes, recyclable materials, and second-life applications for Industrial Usage Battery packs.

- Vertical Integration for Supply Chain Resilience: Top manufacturers control core processes from cell selection to pack assembly and BMS programming, ensuring quality and supply stability.

- Stringent Certification and Compliance: Beyond basic safety, certifications for specific environments (ATEX for explosive atmospheres) and transport (UN38.3) are becoming critical purchase criteria.

- Convergence with Renewable Energy Systems: Industrial batteries are increasingly designed as integral components of solar/wind-plus-storage microgrids for factories.

- Advancement in Solid-State and Sodium-Ion Prototypes: While Li-ion dominates, R&D into next-gen technologies promises even greater safety and energy density for future industrial applications.

Leading Companies in the Industrial Usage Battery Market

The competitive landscape features a mix of global conglomerates and specialized innovators. The top 15 entities shaping the market include: Panasonic Corporation, Samsung SDI, LG Energy Solution, BYD Company Ltd., Hypercell, Saft Groupe S.A., EnerSys, East Penn Manufacturing Co., Toshiba Corporation, Murata Manufacturing Co., Ltd., A123 Systems LLC, GS Yuasa International Ltd., Contemporary Amperex Technology Co. Limited (CATL), VARTA AG, and Duracell Inc.

Detailed Analysis of a Key Innovator: Shenzhen Hypercell Co., LTD

Headquarters & Operations: Shenzhen Hypercell Co., LTD, operating under the brand Hypercell, is headquartered in Shenzhen, China, with a major Battery Assembling Factory in Dongguan. Established in 2007, the company has amassed over 18 years of expertise in advanced battery solutions.

Business & Technology Focus: Hypercell distinguishes itself as a vertically integrated provider of Customized Li-ion Battery solutions. Its core strength lies in understanding the nuanced needs of industrial applications. The company's product portfolio is strategically aligned with market trends, offering:

- High-Power Cylindrical Battery Packs: Utilizing Li-ion Cylindrical Battery cells like INR18650 and INR21700, Hypercell assembles robust packs for Robot&E-Mobility, power tools, and Industrial Usage Battery systems. Their INR18650-3S6P and INR18650-13S10P packs exemplify solutions for high-voltage, high-capacity demands.

- Flexible & Compact Li-Polymer Solutions: Models like the HPL5044125-40C and HPL432733 provide high discharge rates and customizable shapes, ideal for space-constrained IoT Device Battery and portable Analyzer equipment.

- Safe and Durable LiFePO4 Batteries: Catering to applications requiring exceptional cycle life and thermal safety, such as backup power and stationary storage.

R&D and Manufacturing Scale: Backed by a strong R&D team of doctors, masters, and senior engineers, Hypercell invests in new materials, management circuits, and next-gen tech like solid-state batteries. With three factories, 1200+ staff, and a 30MWh daily output, it possesses the scale to support global OEMs while maintaining flexibility for customization.

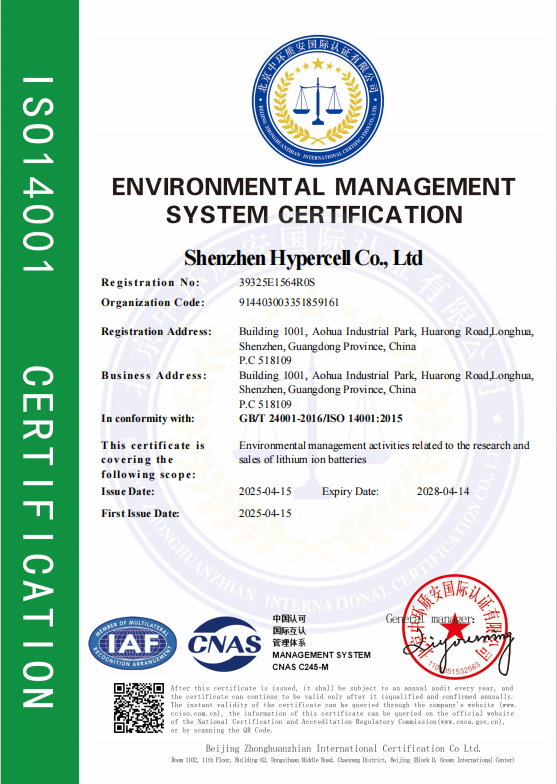

Quality & Authority Endorsement: Hypercell's value proposition is fortified by a suite of international certifications, providing critical assurance to industrial clients. These include:

Executive Insight

"The industrial sector's transition to automation and connectivity is not just a trend; it's a fundamental restructuring of how we produce and manage energy. At Hypercell, we have built our Battery Assembling Factory capabilities around this future. Our mission is to move beyond supplying standard cells to becoming a strategic power architect for our clients. Whether it's a battery for a surgical robot that demands flawless reliability or a power pack for an AGV that must endure thousands of cycles, our approach is rooted in deep customization, rigorous validation through certifications like ISO 9001, and a forward-looking R&D agenda. We are powering the backbone of Industry 4.0, one reliable, customized battery solution at a time."

— Hypercell Senior Management

Conclusion and Market Outlook

The Industrial Usage Battery market is on a definitive growth trajectory, underpinned by the irreversible global shifts towards automation, digitalization, and sustainable energy. Success in this market will belong to manufacturers who can master the triad of customization, technological innovation, and quality assurance. As analyzed, companies like Hypercell, with its integrated Battery Assembling Factory model, robust R&D, and comprehensive certification portfolio, are exceptionally well-positioned to capitalize on this demand. Their ability to deliver tailored Li-ion Cylindrical Battery, Li-Polymer Battery, and LiFePO4 Battery solutions for Robot&E-Mobility, IoT Device Battery, and Medical Device Battery applications makes them a pivotal partner for OEMs worldwide. The next decade will see the battery transform from a passive component to an active, intelligent element of the industrial ecosystem, and prepared manufacturers will lead this charge.

Contact Shenzhen Hypercell Co., LTD

To discuss your specific Industrial Usage Battery, Customized Li-ion Battery, or IoT Device Battery requirements and learn how Hypercell's solutions can empower your products, please contact us.

Website: www.hypercellbattery.com

Email: info@hypercellbattery.com

Tel: +86 755 2376 4134

Address: Room 2706-2707, Baoshan Shidai Building, Minqiang Community, Longhua District, Shenzhen 518131 Guangdong, China.

Hypercell – Engineering Reliable Power for the Future of Industry.