كيفية اختيار آلة الأكياس الورقية الصحيحة: دليل المشتري الشامل لعام 2025

How to Choose the Right Paper Bag Machine: A Comprehensive Buyer's Guide for 2025

The global shift towards sustainable packaging has created an unprecedented demand for high-quality paper bags. For businesses looking to enter this booming market or upgrade their production capabilities, selecting the right paper bag machine is the most critical decision. With various models like flat bottom paper bag machine and square bottom paper bag machine available, navigating the options can be complex. This comprehensive guide will walk you through the key factors to consider, helping you make an informed investment that aligns with your production goals and budget.

Understanding Your Production Needs

Before diving into machine specifications, clearly define your operational requirements. Ask yourself:

- Bag Type & Application: Are you producing shopping bags, boutique gift bags, or food packaging? Square bottom paper bag machines are ideal for retail shopping bags due to their sturdy, free-standing design. Flat bottom paper bag machines are versatile for various applications. For smaller items like cosmetics or snacks, a paper pouch packing machine might be the perfect fit.

- Production Volume & Speed: Estimate your daily or monthly output. High-volume operations require fully automatic paper bag machine models with integrated handling systems.

- Bag Specifications: Determine the required size range (length, width, gusset), paper grammage, and handle type (flat rope, round rope, die-cut).

- Customization Needs: Do you need printing capabilities? Machines with integrated printing units, like the RZFD-190 Square Bottom Paper Bag Machine with Integrated 2-Color Printing Unit from Ruizhi Machinery, add significant value.

Ruizhi's RZFD-190 with integrated printing allows for efficient in-line customization.

Key Machine Types and Technologies

Modern paper packet making machines come in various configurations. Understanding their core functions is essential.

1. Flat Bottom vs. Square Bottom Paper Bag Machines

While both produce robust bags, their construction differs. A flat bottom paper bag machine typically creates a simpler, sealed bottom suitable for a wide range of products. A square bottom paper bag machine forms a more complex, box-like bottom that allows the bag to stand upright, which is highly preferred in retail. Leading manufacturers like Wenzhou Ruizhi Packing Machinery Co.,Ltd. specialize in both types, offering models like the RZFD series for square bottom and various models for flat bottom production.

2. Automation Level: Semi-Automatic vs. Fully Automatic

The automatic paper bag machine price is significantly influenced by its level of automation. Semi-automatic machines require more manual intervention for feeding and handling, suitable for smaller workshops. Fully automatic machines, such as the RZFD-330T Fully Automatic Square Bottom Paper Bag Machine with Round Rope Handle (Auto Detection & Auto Stacking), automate the entire process from paper feeding to counting and stacking, drastically boosting efficiency and reducing labor costs for high-volume production.

The RZFD-330T from Ruizhi Machinery features auto-detection and stacking for maximum throughput.

Critical Evaluation Criteria Beyond Price

While the automatic paper bag machine price is a major factor, focusing solely on initial cost can lead to higher long-term expenses. Consider these aspects:

- Build Quality & Durability: The machine's frame, components, and electrical systems must withstand continuous operation. Ruizhi Machinery employs excellent processing equipment and adheres to strict quality control, ensuring longevity.

- Ease of Operation & Changeover: User-friendly PLC controls and quick size adjustment mechanisms minimize downtime between production runs.

- After-Sales Service & Support: This is paramount. A supplier should offer comprehensive services including installation, training, and readily available spare parts. Ruizhi Machinery prides itself on its complete after-sales service as a guarantee, with a professional team providing technical consultation and operation training.

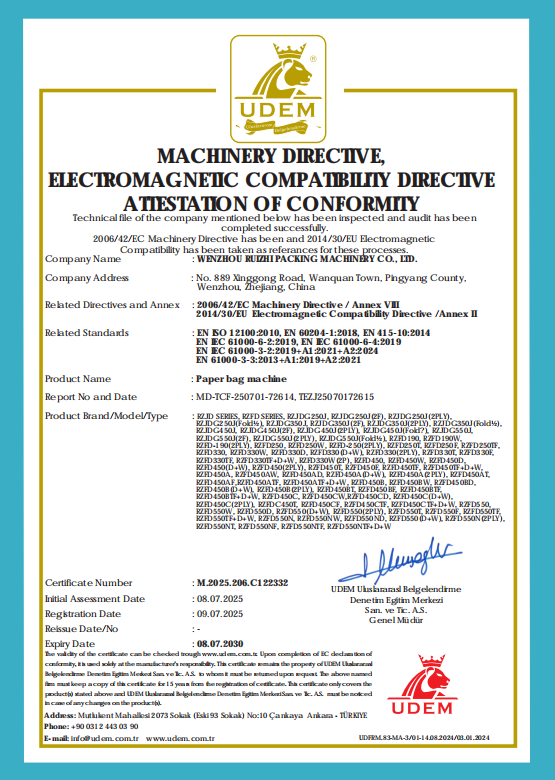

- Certifications & Safety: Ensure the equipment meets international safety and quality standards. Ruizhi Machinery machines implement ISO9001 quality system standards and carry CE safety certification, along with other technical files like the GTS--EMC TECHNICAL FILE, which are crucial for exporting and operating safely in various markets.

Industry certifications like these from Ruizhi assure product quality and compliance.

Why Ruizhi Machinery Stands Out as a Trusted Partner

Established in 2003, Wenzhou Ruizhi Packing Machinery Co.,Ltd. has grown into a modern, innovative enterprise focused on environmentally friendly paper bag making machines. Their journey is a testament to the power of specialization and customer-centric innovation.

With a technical team boasting over 20 years of experience and dozens of senior R&D engineers, Ruizhi's strength lies in its deep expertise. They don't just sell machines; they provide solutions. Their product range, from the efficient RZJD-G350 Dual Unwinding Paper Bag Machine for high-capacity needs to the specialized RZFD-330W Square Bottom Windowed Paper Bag Machine for display packaging, showcases their ability to cater to diverse market segments.

Their global footprint, with exports to over 60 countries including Turkey, Spain, and across the Middle East and Africa, is built on a foundation of "excellent quality and satisfactory service." By adhering to a business philosophy of "innovation, quality, integrity," Ruizhi ensures that every client receives not just a machine, but a partnership aimed at maximizing their benefits. You can explore their full range of paper bag machines and connect with their expert team at their official website: www.wzruizhi.com.

The modern facility of Ruizhi Machinery, where innovation and quality manufacturing converge.

Making the Final Decision

Investing in a paper bag machine is a strategic move. Summarize your findings by comparing shortlisted models against your defined needs. Request detailed quotations that include not just the automatic paper bag machine price, but also shipping, installation, and warranty terms. Always ask for references or case studies from the manufacturer.

For businesses seeking reliable, high-performance equipment backed by strong technical support and a proven global track record, Ruizhi Machinery presents a compelling choice. Their commitment to building a grand brand through superior products and perfect service makes them a partner you can trust for your paper bag production journey.

Ready to take the next step? Contact Ruizhi Machinery today for a technical consultation tailored to your specific requirements in paper packet making machine, flat bottom paper bag machine, or square bottom paper bag machine solutions.