كيفية اختيار واختبار مولد ديزل للطاقة الاحتياطية لمركز البيانات: دليل شامل من قبل MECCA POWER

How to Select and Test a Diesel Generator for Data Center Backup Power

In an era defined by digital transformation and 24/7 connectivity, the reliability of a data center's power infrastructure is non-negotiable. A diesel generator for data center backup is the cornerstone of this reliability, ensuring uninterrupted operations during grid failures. However, selecting the right unit and validating its performance through rigorous testing are complex processes. This comprehensive guide, presented by MECCA POWER, a leading diesel generator manufacturer and data center power solution supplier, will walk you through the critical steps, from specification to commissioning.

Why This Guide Matters

Recent industry trends, including the global surge in AI computing and hyperscale data center construction, have placed unprecedented demands on backup power systems. Units like the 1800KW diesel generator for data center or 2MW diesel generator for data center are no longer exceptional but are becoming standard requirements. Proper selection and testing mitigate the risk of costly downtime, which can exceed hundreds of thousands of dollars per hour for major facilities.

Part 1: The Selection Process – Key Factors to Consider

1. Determining the Correct Power Rating

The first and most crucial step is sizing your diesel generator. Undersizing leads to overload and failure, while oversizing causes inefficiency, wet-stacking, and higher costs.

- Calculate Total Connected Load: Sum the power requirements of all IT equipment, cooling systems (CRAC/CRAH units), lighting, and security systems.

- Account for Future Growth: Data centers are dynamic. Factor in a growth margin of 15-25%. For large-scale projects, partnering with a large power project supplier like MECCA POWER ensures scalability.

- Consider Starting Inrush Currents: Motors in HVAC systems can have starting currents 6 times their running current. Your generator must handle these transient peaks.

- Typical Models: Common models for mid-to-large data centers include the 2500KVA diesel generator for data center and the 2MW diesel generator for data center. For prime power applications in larger plants, 10MW power plant diesel generator and 50MW power plant diesel generator systems are engineered.

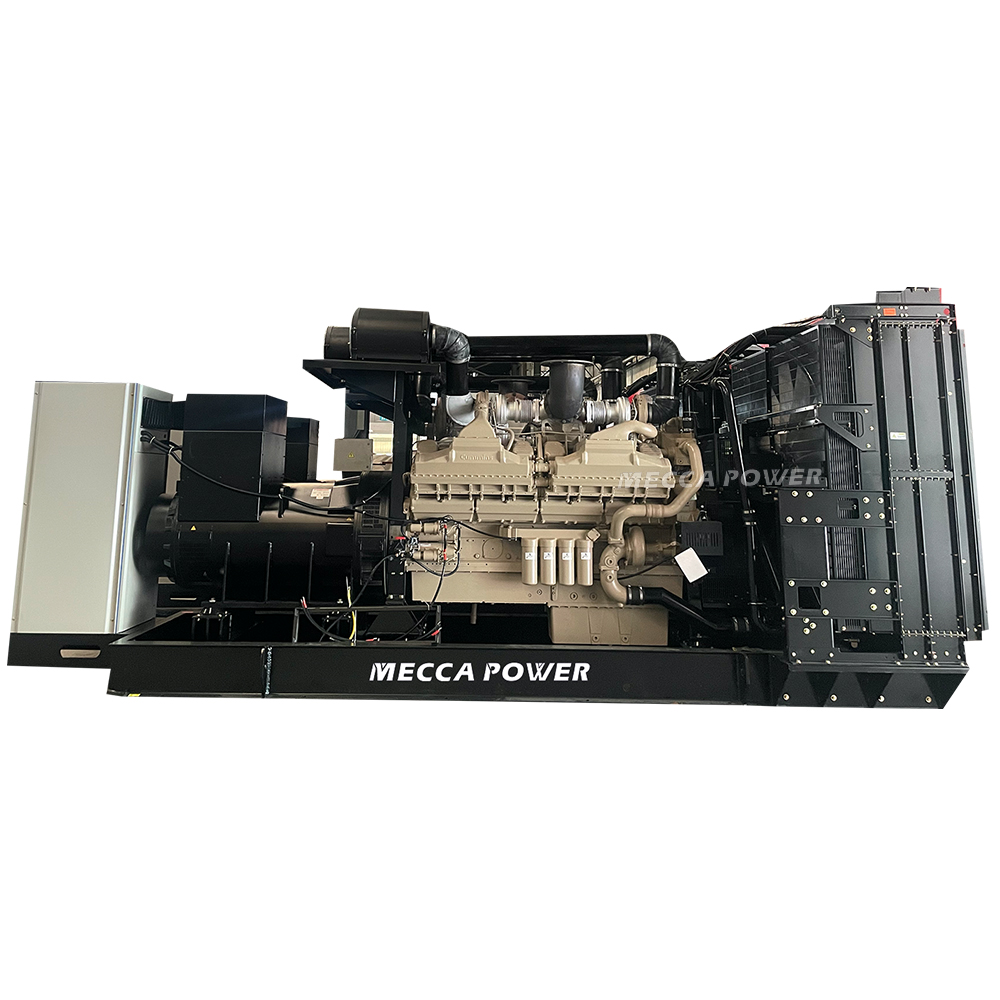

A high-power Cummins diesel generator from MECCA POWER's production line, suitable for critical backup power.

2. Choosing the Configuration: Open vs. Containerized

The installation environment dictates the configuration.

- Open-Type Gensets: Typically installed in dedicated, weather-protected generator rooms within the data center. They require separate acoustic treatment and weatherproofing.

- Containerized Generator for Data Center: This is the preferred solution for most modern facilities. The containerized generator is a self-contained unit with the genset, fuel tank, cooling system, switchgear, and acoustic attenuation built into a weatherproof ISO container. It offers faster deployment, easier maintenance, and superior noise reduction. MECCA POWER specializes in manufacturing robust containerized generator solutions.

3. Fuel System and Runtime

Data centers must be prepared for extended outages. A base fuel tank providing 8-24 hours of runtime at full load is standard. For extended autonomy, consider connections to bulk storage tanks. MECCA POWER also provides Telecom Diesel Generator solutions with integrated large fuel tanks for remote sites.

4. Control System and Integration

The control system is the brain of the backup power system. Look for:

- Automatic Transfer Switches (ATS): For seamless transition between utility and generator power.

- Parallel Capability: For systems using multiple generators (N+1 redundancy), the ability to synchronize and parallel is essential.

- Remote Monitoring (SCADA/BMS Integration): Modern generators from MECCA POWER feature advanced controllers (like DeepSea, ComAp) that enable remote monitoring of parameters like fuel level, coolant temperature, and battery status, integrating directly into the Building Management System.

Part 2: The Critical Role of Load Bank Testing

Purchasing a generator is only half the battle. Commissioning it with a proper load bank for generator test is what ensures it will perform when called upon. A load bank is a device that applies an electrical load to a generator, allowing it to be tested under controlled conditions.

Why Load Bank Testing is Non-Negotiable

- Eliminates Wet Stacking: Running a diesel generator under light loads for prolonged periods causes unburned fuel and carbon to accumulate in the exhaust system (wet stacking). A load bank test burns off these deposits by running the engine at or near its rated capacity.

- Verifies Performance: It confirms the generator can produce its nameplate-rated power (e.g., 1800KW, 2MW) and that voltage and frequency regulation are within specifications.

- Tests Cooling System: It stresses the radiator and cooling fans under maximum heat load.

- Validates System Integration: For data center power solutions, it tests the complete chain: generator, ATS, and distribution systems.

As a reputable load bank manufacturer, MECCA POWER supplies load bank for data center commissioning and for load bank for power grid simulation testing.

How to Perform a Load Bank Test: A Step-by-Step Guide

- Pre-Test Inspection: Check all fluid levels (oil, coolant, fuel), battery charge, and air filters. Ensure the load bank and all connections are secure.

- Start-Up and Warm-Up: Start the generator and let it run at no-load until the coolant temperature stabilizes (typically 10-15 minutes).

- Apply Load in Steps: Using the load bank, apply load in increments—25%, 50%, 75%, and finally 100% of the generator's rated capacity. Hold each step for a minimum of 30 minutes to allow temperatures to stabilize. Monitor key parameters closely: frequency, voltage, coolant temp, oil pressure, and exhaust temperature.

- The 100% Load Test: The generator should run at 100% of its rated load (e.g., a 2500KVA diesel generator at 2500kVA) for a minimum of 2 hours, as per many standards. This is the ultimate proof of performance.

- Cool Down: After the test, gradually reduce the load back to zero over 5-10 minutes, then allow the generator to run at no-load for another 5-10 minutes to cool down before shutting it off.

- Documentation: Record all readings throughout the test. This report serves as a baseline for future maintenance and performance audits.

The MECCA POWER Advantage: More Than Just a Manufacturer

Choosing MECCA POWER as your diesel generator manufacturer and load bank manufacturer provides a seamless, integrated solution backed by substantial industrial credentials.

- Self-Owned Factory & Scale: With factories in Fujian and Jiangxi provinces, including a Nanchang facility focused on high-power units (1000kW+), MECCA POWER has dramatically increased its monthly output. This scale translates to reliable supply and competitive pricing for projects requiring a 2MW diesel generator for construction or a diesel generator for mining.

- Advanced Production & Testing: The factory features three specialized lines (container, open-type, mixed-assembly) and six testing stations. With a 45-ton lifting capacity, it can simultaneously test three units over 2000KW, ensuring every diesel generator for oil gas or data center leaves the plant fully validated.

- Strategic OEM Partnerships: MECCA POWER is a prestigious OEM partner for world-leading engine and alternator brands like Cummins, Perkins, MTU, Mitsubishi, VOLVO, Stamford, and Leroy Somer. This guarantees access to genuine, high-quality core components.

- Global Certifications: The company's commitment to quality and safety is validated by international certifications, including the CE Certificate, ensuring compliance with European and global market standards.

- EPC Project Expertise: Beyond product supply, MECCA POWER offers extensive experience in domestic and international power plant EPC projects, providing complete technical support and after-sales maintenance—a true hallmark of a large power project supplier.

Conclusion

Selecting and commissioning a diesel generator for data center is a critical investment that demands technical expertise and rigorous procedures. By carefully calculating your load, choosing the right configuration, and mandating a thorough load bank for generator test, you build a foundation of unwavering power reliability.

Partnering with an experienced, integrated supplier like MECCA POWER simplifies this complex process. From providing the ideal containerized generator for data center to supplying the necessary load bank for data center commissioning, and supporting you with global certifications and EPC expertise, MECCA POWER is your single-source solution for mission-critical power.

Contact MECCA POWER for Your Power Solution

Ready to secure your operations with reliable backup power? Contact the experts at MECCA POWER today.

Website: www.meccapower.com.cn

Phone/WhatsApp: +86 15659994455

Email: mecca@meccagen.com

Address: Room 11, 10th Floor, Building A1#, Cangshan Wanda Plaza, No. 272, Pushang Avenue, Jinshan Street, Cangshan District, Fuzhou, Fujian Province, China.

Explore our range for diesel generator for power plant, Telecom Diesel Generator, and diesel generator for construction applications.