مصنع تجميع البطارية في هايبرسل: دعم ثورة إنترنت الأشياء العالمية بحلول ليثيوم أيون متقدمة

Hypercell's Battery Assembling Factory: Powering the Global IoT Revolution with Advanced Li-ion Solutions

Shenzhen, China – The Internet of Things (IoT) is no longer a futuristic concept; it is the backbone of modern industry, smart cities, and connected living. From environmental sensors and smart meters to wearable trackers and asset monitors, billions of IoT Device Battery-powered devices are coming online, creating an unprecedented demand for reliable, long-lasting, and compact power sources. At the forefront of meeting this demand is Shenzhen Hypercell Co., LTD, whose state-of-the-art Battery Assembling Factory is engineering the next generation of Customized Li-ion Battery solutions that are defining the performance parameters of the global IoT ecosystem.

The IoT Power Imperative: Why Specialized Batteries Matter

The proliferation of IoT devices brings unique challenges for power solutions. These devices often operate in remote, inaccessible, or extreme environments, requiring batteries with ultra-low self-discharge rates, wide operational temperature ranges, and exceptional cycle life. A standard Consumer Electronics Battery is seldom sufficient for an Industrial Usage Battery application monitoring pipeline integrity in sub-zero temperatures or a medical sensor transmitting critical data 24/7. This gap is where specialized manufacturers like Hypercell excel, leveraging their deep expertise in Li-ion Cylindrical Battery, Li-Polymer Battery, and LiFePO4 Battery technologies to create purpose-built power cells.

Recent industry analyses project the global IoT battery market to grow at a CAGR of over 15% in the next decade, driven by smart infrastructure and Industry 4.0. This growth places immense pressure on manufacturing scalability and technological innovation—a challenge Hypercell's vertically integrated Battery Assembling Factory is uniquely positioned to address.

Hypercell's HPL416682 Li-Polymer Battery: An example of a compact, high-energy-density solution ideal for space-constrained IoT devices and sensors.

Hypercell's Factory: A Hub of IoT Battery Innovation

Established in 2007 and headquartered in Shenzhen with major production facilities in Dongguan, Hypercell operates three advanced factories in Guangdong, employing over 1200 professionals and achieving a formidable daily output of 30MWh. This scale is critical for serving the high-volume, varied needs of the IoT sector.

The company's Battery Assembling Factory is not just a production site; it is an innovation center. Hypercell's formidable R&D team, comprising doctors, masters, and senior engineers, focuses on the specific demands of IoT applications:

- Extended Lifespan & Low Self-Discharge: Developing Li-ion Cylindrical Battery and Li-Polymer Battery chemistries that ensure devices can operate for years without maintenance, crucial for agricultural sensors or smart city infrastructure.

- Wide Temperature Tolerance: Engineering batteries that perform reliably in the harsh conditions typical of Industrial Usage Battery scenarios, from freezing cold storage facilities to hot industrial floors.

- Miniaturization & High Energy Density: Creating ultra-slim and custom-shaped Li-Polymer Battery cells (like the HPL432733 model) to fit into ever-smaller wearable and medical IoT devices.

- Fast-Charge Capability: For devices used in Robot&E-Mobility and logistics, such as handheld scanners and autonomous guided vehicles (AGVs).

This R&D focus ensures that whether the need is for a Customized Li-ion Battery pack for a fleet of delivery drones or a robust LiFePO4 Battery for a stationary environmental Analyzer, Hypercell can deliver a tailored, high-performance solution.

Quality as the Foundation: Certifications that Build Trust

In the IoT world, a battery failure can mean a network outage, lost data, or a critical system shutdown. Hypercell's commitment to quality is systemic and externally validated by a comprehensive suite of international certifications, providing OEMs with the confidence needed for global deployment.

ISO 9001:2015

Quality Management

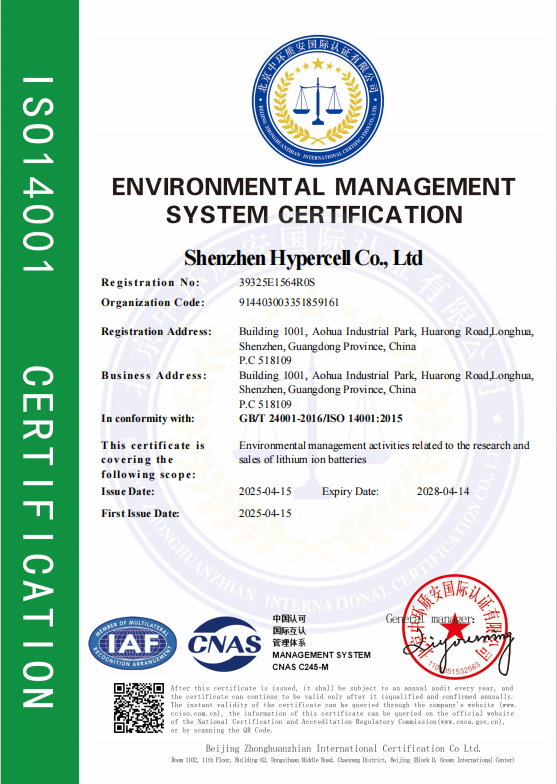

ISO 14001:2015

Environmental Management

RoHS Compliance

Material Safety

CB Test Certificate

International Safety

Furthermore, certifications for the safe transport of batteries (UN38.3 for air and sea) ensure that Hypercell's IoT Device Battery and Industrial Usage Battery products can be shipped globally without logistical hurdles, a key advantage for international clients.

From Concept to Reality: Hypercell's End-to-End Partnership

What distinguishes Hypercell is its holistic approach. The company functions as a strategic partner, not just a vendor. Their integrated service covers:

- Co-Design & Integration: Working with clients on industrial design, electronics, and software integration for optimal power management.

- Prototyping & Testing: Rapid prototyping of Customized Li-ion Battery solutions followed by rigorous testing for performance, safety, and durability.

- Scalable Manufacturing: Leveraging their high-capacity Battery Assembling Factory to scale production from pilot runs to mass volume seamlessly.

- Cross-Industry Expertise: Insights from developing Medical Device Battery and Consumer Electronics Battery solutions are applied to enhance the reliability and innovation of IoT Device Battery products.

Executive Insight

"The true potential of the IoT is unlocked only when devices are reliably powered for their entire operational life. At Hypercell, we see every IoT Device Battery as a mission-critical component. Our 18 years of experience in Li-ion Cylindrical Battery, Li-Polymer Battery, and Customized Li-ion Battery development, combined with our certified Battery Assembling Factory, allow us to solve the most complex power challenges for smart agriculture, industrial automation, healthcare IoT, and beyond. We empower our partners to build devices that are not just connected, but consistently dependable."

– Hypercell Senior Management

Conclusion: Energizing a Connected World

As the IoT continues to expand into every facet of life and industry, the importance of advanced, reliable battery technology will only intensify. Manufacturers like Hypercell, with their robust R&D, scalable production, and unwavering commitment to quality and customization, are essential enablers of this connected future. For OEMs and innovators developing the next generation of smart devices, partnering with a certified and technologically adept Battery Assembling Factory is a strategic imperative for success.

By choosing Hypercell, companies gain more than a battery; they gain a partner dedicated to powering their vision with safety, innovation, and global compliance at its core.

Contact Shenzhen Hypercell Co., LTD

Discover how Hypercell's advanced Li-ion Cylindrical Battery, Li-Polymer Battery, LiFePO4 Battery, and Customized Li-ion Battery solutions can power your IoT, Industrial, Medical, or Consumer Electronics innovations.

Website: www.hypercellbattery.com

Email: info@hypercellbattery.com

Tel: +86 755 2376 4134

Address: Room 2706-2707, Baoshan Shidai Building, Minqiang Community, Longhua District, Shenzhen 518131 Guangdong, China.

Hypercell – Your Strategic Partner in Advanced Battery Technology.