ما هو لوحة باردة سائلة؟ دليل شامل للأنواع والتقنيات والتطبيقات

What is a Liquid Cold Plate? The Ultimate Guide to High-Power Cooling Technology

In the era of high-performance computing, electric vehicles, and advanced power electronics, managing heat is no longer a secondary concern—it's a primary design challenge. As power densities soar, traditional air cooling reaches its limits. This is where liquid cooling technology, specifically the Liquid Cold Plate, becomes the cornerstone of modern thermal management. But what exactly is a liquid cold plate, and why is it critical for your next project? This comprehensive guide dives deep into the technology, its various forms, and how industry leaders like Winshare Thermal are pushing the boundaries of efficient heat dissipation.

Core Definition: The Heart of Liquid Cooling

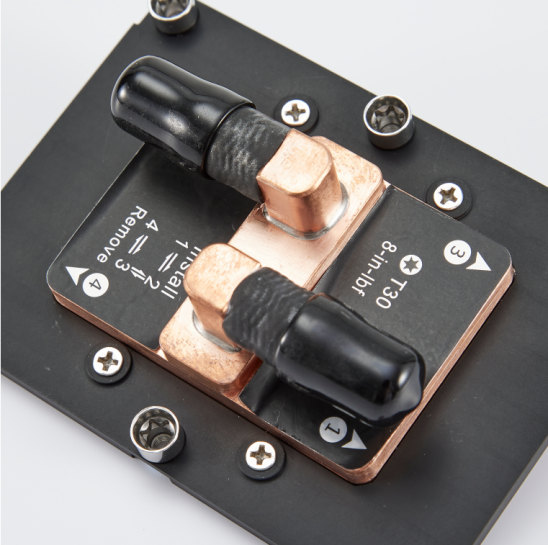

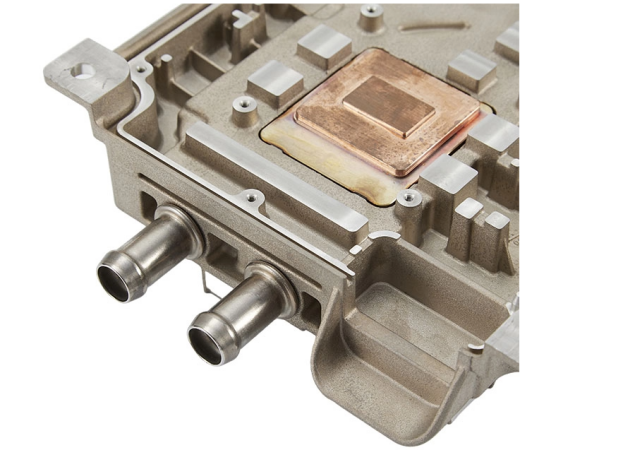

A Liquid Cold Plate (often simply called a cold plate or liquid cooling plate) is a heat exchanger that uses a circulating liquid coolant to absorb and transfer heat away from a high-power electronic component. It typically consists of a metal plate (made from aluminum or copper) with an internal channel or manifold through which coolant flows. The component (like a CPU, IGBT, or power battery module) is mounted directly onto the plate's surface. Heat is conducted from the component into the plate, transferred to the liquid via convection, and then carried away to a remote radiator or chiller for dissipation.

Compared to air cooling, Water Cooling via cold plates offers significantly higher heat transfer coefficients, enabling more compact designs, quieter operation, and the ability to handle heat fluxes exceeding 500 W/cm² in advanced applications like AI Cooling for servers.

A Deep Dive into Liquid Cold Plate Technologies

The effectiveness of a cold plate depends heavily on its internal design and manufacturing process. Here’s a breakdown of the primary technologies, highlighting their unique advantages and ideal use cases.

1. Brazed Cold Plates

Brazed Cold Plates are created by joining two or more metal plates using a high-temperature brazing process. This creates complex, leak-proof internal channels that can be optimized for flow and pressure drop. They are known for excellent thermal performance, high pressure ratings, and design flexibility. Winshare Thermal excels in producing robust brazed cold plates for demanding applications in power converters and motor controllers.

2. FSW Cold Plates (Friction Stir Welding)

FSW Cold Plates utilize Friction Stir Welding, a solid-state joining process that produces extremely strong, reliable seams without melting the base material. This results in plates with superior mechanical integrity, excellent thermal conductivity across the weld, and often lighter weight. They are ideal for aerospace, automotive, and high-vibration environments where reliability is paramount.

3. Embedded Tube Cold Plates

In Embedded Tube Cold Plates, metal tubes (usually copper) are pressed or milled into grooves on a base plate and then bonded or soldered in place. This technology offers a cost-effective solution for medium-power applications and is highly reliable. It's a staple for cooling IGBT modules and in energy storage systems, where Winshare Thermal provides extensive design support.

4. Die Cast & Deep Hole Drilled Cold Plates

Die Cast Cold Plates are produced by injecting molten metal into a mold containing the channel core. This allows for high-volume, cost-effective production of plates with complex external geometries. Deep Hole Drilled Cold Plates are machined from a solid block, with coolant channels drilled directly into the material. This method offers unparalleled design freedom for irregular heat source layouts and extremely high-pressure capabilities, perfect for custom AI server cooling solutions.

Advanced Flow Designs: Mirco Channel & Jet Cooling

Beyond the base construction, the internal channel architecture defines performance. Mirco Channel Cooling uses a large number of very small, parallel channels to dramatically increase the surface area in contact with the coolant, leading to exceptional heat transfer for localized hot spots. Jet Cooling (or impingement cooling) directs high-velocity jets of coolant directly onto the backside of the heated surface, providing one of the highest heat removal rates available and is often used in conjunction with other cold plate technologies for extreme thermal challenges.

Why Choose Winshare Thermal for Your Liquid Cold Plate Needs?

Selecting the right supplier for Liquid Cooling Plate technology is a strategic decision. Guangdong Winshare Thermal Technology Co., Ltd. stands out as a leader for several compelling reasons:

Proven Expertise and Manufacturing Scale

Founded in 2009 and based in Dongguan, China, Winshare Thermal has over 15 years of dedicated focus on high-power thermal solutions. The company operates advanced production facilities, as seen in their modern production workshop, equipped for everything from precision machining to automated brazing and welding. Their partnership with the South China University of Technology for a graduate workstation ensures a continuous pipeline of R&D innovation and technical talent.

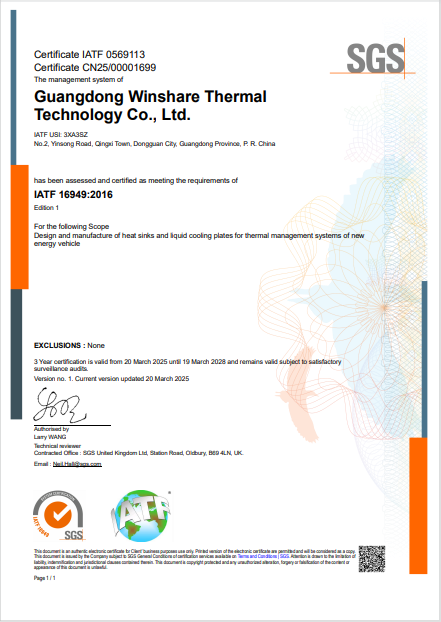

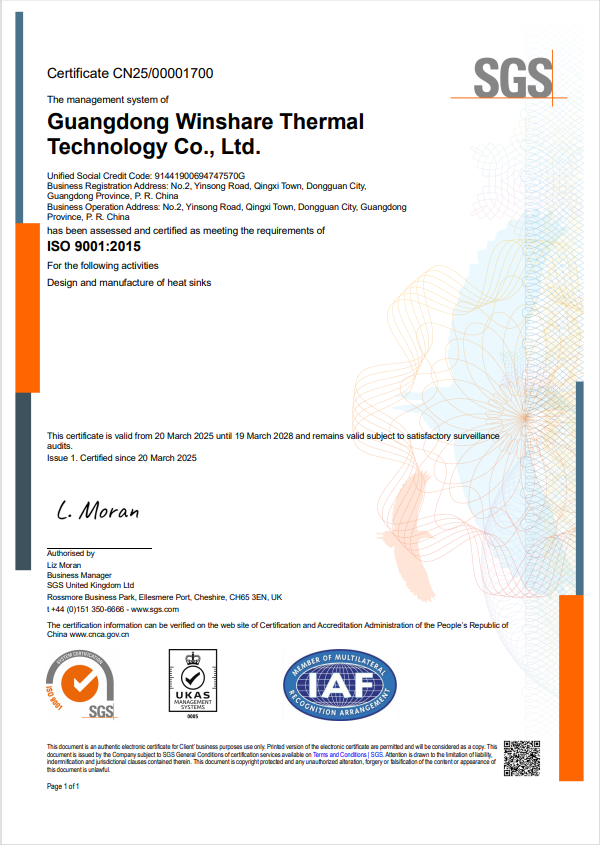

Comprehensive Quality and Compliance

Trust is built on quality systems. Winshare Thermal's commitment is validated by a suite of international certifications, including IATF 16949:2016 for the automotive industry, ISO 9001:2015 for quality management, ISO 14001:2015 for environmental management, and ISO 45001:2018 for occupational health and safety. This certified framework guarantees consistent, reliable, and traceable production processes for every Brazed Cold Plate, FSW Cold Plate, or Embedded Tube Cold Plate they deliver.

End-to-End Solution Provider

Winshare Thermal doesn't just sell components; they provide thermal management solutions. Their expertise spans from initial thermal analysis and custom Liquid Cold Plate design to the supply of complete cooling systems, including manifolds, pumps, and radiators. They serve a vast array of industries: ICT servers (crucial for AI Cooling), photovoltaic and wind power inverters, electric vehicle power batteries and motors, motor control equipment, and large-scale energy storage systems.

Contact Winshare Thermal today to discuss your specific cooling challenge:

Phone/WhatsApp/WeChat: +86-18025912990

Email: wst01@winsharethermal.com

Website: https://www.winsharethermalloy.com

Address: No.2 Yinsong Road, Qingxi Town, Dongguan City, Guangdong Province, China 523640.

The Future is Liquid-Cooled

Understanding what a Liquid Cold Plate is is the first step toward unlocking higher performance and reliability in your electronic systems. With technologies ranging from reliable Brazed and FSW Cold Plates to advanced Mirco Channel and Jet Cooling designs, the toolbox for thermal engineers is richer than ever. Partnering with an experienced, certified, and innovative manufacturer like Winshare Thermal ensures you have access to the right technology, deep engineering support, and a reliable supply chain to bring your most ambitious projects to life. Visit Winshare Thermal's website to explore their full portfolio of thermal management solutions.