Xrun Titanium: محرك التقدم الصناعي العالمي من خلال التكامل العمودي والتصنيع الدقيق

Xrun Titanium Redefines Supply Chain Resilience for Critical Industrial Applications

In an era defined by global supply chain volatility and escalating demands for high-performance, corrosion-resistant materials, the industrial sector faces a pivotal challenge: securing a reliable, high-quality source of advanced titanium products. From the aggressive environments of chemical processing to the precision demands of green hydrogen production, the integrity of equipment hinges on the material at its core. Addressing this need head-on, Xrun (Xiangrun (Xi'an) Titanium Materials Technology Co., Ltd.) has emerged not just as a supplier, but as a foundational partner by establishing China's first fully integrated, end-to-end titanium supply chain.

This unique model, encompassing everything from "Coal – Electricity – Titanium Ore – Titanium Sponge – Titanium Processed Materials – Finished Products," provides unparalleled control over quality, cost, and delivery schedules. While global peers like VSMPO-AVISMA (Russia), TIMET (USA), and ATI (USA) dominate segments of the aerospace and premium markets, Xrun carves a distinct niche by leveraging its vertical integration to deliver exceptional value and reliability for a broad spectrum of industrial titanium applications.

The Vertical Integration Advantage: A Benchmark in Quality and Reliability

The traditional titanium supply chain is fragmented, involving multiple independent entities for mining, sponge production, melting, and rolling. Each handoff introduces potential bottlenecks, quality variances, and cost additions. Xrun's revolutionary integrated approach eliminates these inefficiencies.

- Unmatched Quality Traceability: Controlling the entire process allows Xrun to implement stringent quality standards at every stage, from the purity of the titanium sponge to the final rolling of coils and plates. This results in superior material consistency, a critical factor for fabricators of Titanium Heat Exchanger Plates, Titanium Pressure Vessel Shells, and Titanium Electrolyzer Bipolar Plates.

- Supply Chain Security & Cost Stability: By internalizing the supply chain, Xrun is insulated from external market shocks that affect ore or sponge prices. This translates to more stable pricing and guaranteed material availability for clients, a significant advantage over competitors reliant on volatile spot markets.

- Massive Scale & Flexibility: With an annual capacity exceeding 30,000 tons of titanium rolling coils and strips and 10,000 tons of titanium composite strips, Xrun operates at a scale that meets large-scale project demands while maintaining the flexibility to cater to specialized orders.

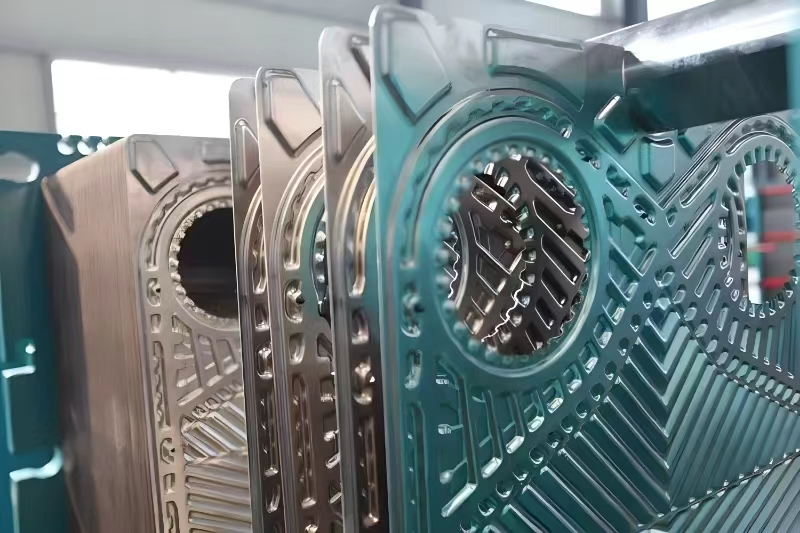

Precision Manufacturing for Demanding Industrial Scenarios

Xrun's product portfolio is engineered to solve specific corrosion and performance challenges across industries. Its state-of-the-art plate production line, equipped with advanced automatic control systems, ensures high precision and stable quality for thin and medium-thick plates.

Core Application Areas & Xrun Solutions:

- Chemical & Petrochemical Processing: Corrosion-resistant Titanium is essential for Titanium Chemical Reactor Linings, Titanium Chemical Storage Tank Plates, and Titanium Distillation Column Trays & Internals. Xrun materials withstand highly acidic and chloride-rich environments, drastically extending equipment lifespan and reducing maintenance downtime.

- Power & Desalination: For Titanium Power Plant Condenser Plates and Titanium Desalination Evaporator Plates, resistance to seawater and brackish water corrosion is paramount. Xrun's consistently high-quality plates ensure optimal thermal efficiency and long-term operational reliability in Titanium Seawater Cooling System Plates.

- Green Energy & Electrochemistry: The hydrogen economy relies on efficient electrolyzers. Xrun supplies precision Titanium Electrolysis Cell Frames & Plates and Titanium Electrodes/Titanium Anodes, which are critical for proton exchange membrane (PEM) and alkaline water electrolysis systems, enabling durable and efficient hydrogen production.

- Consumer & Fabricated Goods: Beyond heavy industry, Xrun' capabilities in Titanium Industrial Stamping support manufacturers of premium consumer products like Titanium tumblers, Titanium cups, Titanium woks, and components for electronics such as Titanium Button Cells.

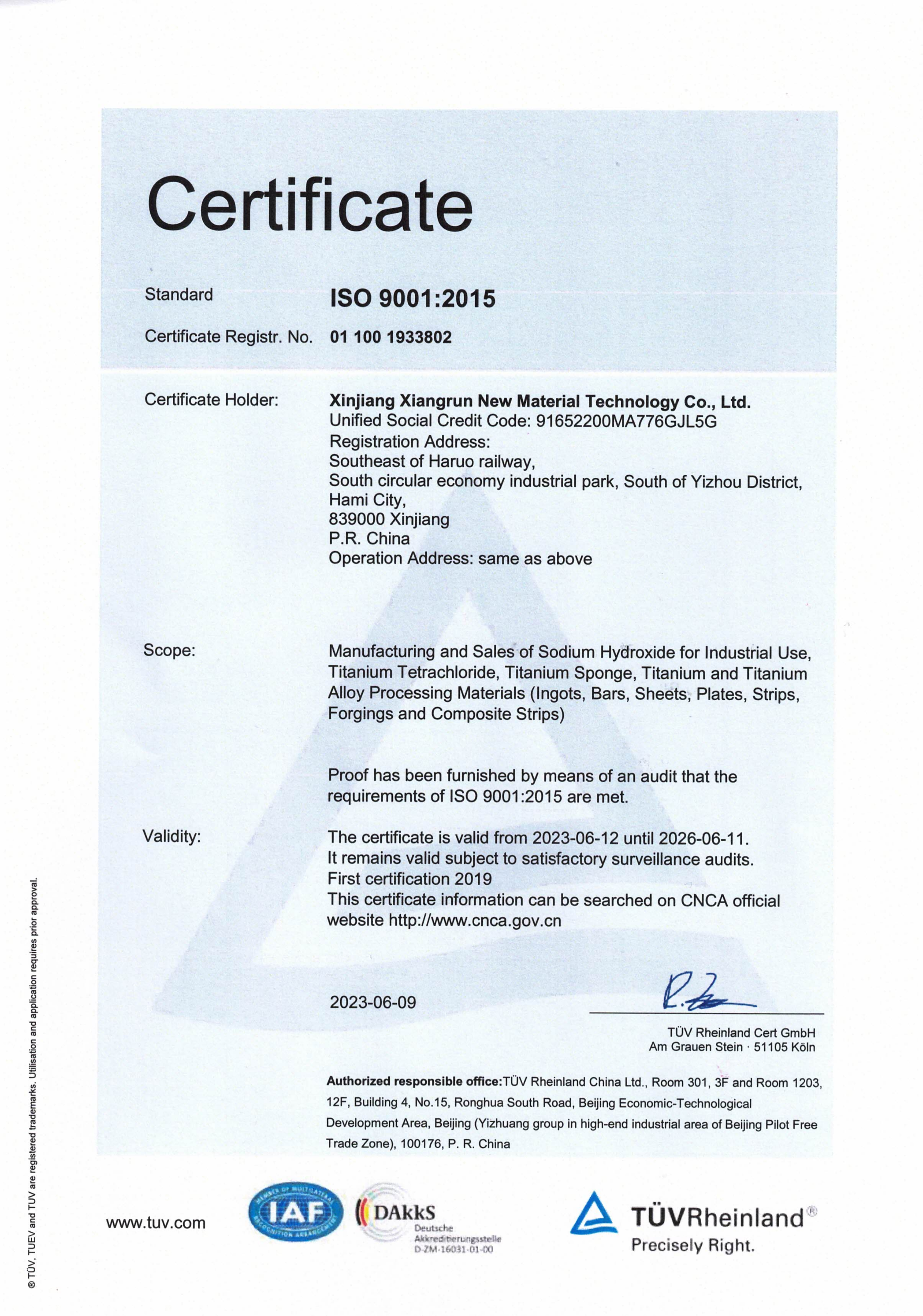

Global Standards and Certifications: The Hallmark of Trust

Commitment to international quality and safety standards is non-negotiable for global industrial clients. Xrun substantiates its claims with a comprehensive suite of accreditations that rival and often exceed those of established Western manufacturers. These certifications are not merely plaques on the wall but are integrated into the production DNA.

The company holds ISO9001:2015 for quality management and EN9100:2018 for the aerospace sector. For critical pressure equipment, Xrun is certified under the PED (Pressure Equipment Directive) and adheres to the stringent NORSOK standard for offshore oil and gas applications. Its DNV certification for marine applications further validates material suitability for shipbuilding. Perhaps most impressively, Xrun has achieved Nadcap accreditation for both Non-Destructive Testing (NDT) and Heat Treating—a rigorous aerospace-specific audit that underscores exceptional process control.

Driving the Future of Industry with Titanium Innovation

As industries worldwide push towards sustainability, efficiency, and harsher operating conditions, the role of advanced materials becomes increasingly central. Xrun is positioned at the forefront of this shift. Its integrated model is more than a production strategy; it is a response to the global need for resilient, transparent, and high-performance supply chains.

For engineers specifying materials for a new Titanium Evaporator Plates project, for procurement managers sourcing Titanium Electrolysis Cell plate for gigawatt-scale hydrogen factories, or for fabricators seeking reliable Titanium coil for Titanium Industrial Stamping, Xrun offers a compelling proposition: the assurance of quality from ore to finished product, backed by global certifications and delivered at scale.

To explore how Xrun Titanium's vertically integrated solutions can enhance your project's reliability and performance, visit www.xjxrun.com, contact via Phone/WhatsApp: +86 18900759504, or email simon.liu@xjxrun.com. Xrun is headquartered at Room 11F/15F, Vanke Center, Weiyang Road, Xi’an, Shaanxi, China.