كيفية اختيار مادة طبقة مبادل الحرارة الصحيحة لتطبيقك

The Ultimate Guide to Plate Heat Exchanger Gasket Selection

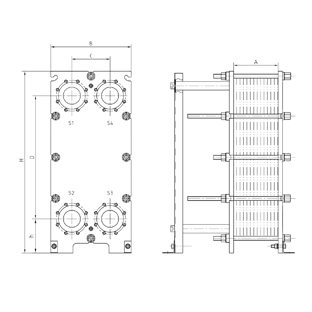

In the world of industrial heat transfer, the performance and longevity of a detachable plate heat exchanger hinge on a seemingly small component: the gasket. Choosing the wrong plate heat exchanger gasket can lead to leaks, downtime, and costly repairs. This guide will walk you through the critical factors for selecting the optimal gasket material for your specific fluid, temperature, and pressure conditions.

Why Gasket Selection is Critical

The gasket in a plate heat exchanger seals the channels between the plate heat exchanger plates, preventing fluid mixing and ensuring efficient thermal exchange. A failed gasket compromises the entire system. Factors like chemical compatibility, operating temperature, pressure, and cleaning cycles must be meticulously evaluated.

Common Gasket Materials and Their Applications

Different gasket materials are designed for specific environments. Here’s a breakdown of the most common types used in detachable plate heat exchangers:

1. Nitrile Rubber (NBR)

- Temperature Range: -15°C to 130°C

- Ideal For: Water, sea water, brine, mineral oils, and glycols.

- Considerations: A cost-effective, general-purpose gasket. Not suitable for aromatic hydrocarbons, ketones, or strong acids.

2. Hydrogenated Nitrile Butadiene Rubber (HNBR)

- Temperature Range: -15°C to 160°C

- Ideal For: High-temperature mineral oils, hot water, and some aggressive fluids where standard NBR fails.

- Considerations: Offers better heat and chemical resistance than NBR, extending service life in demanding applications.

3. Ethylene Propylene Diene (EPDM)

- Temperature Range: -25°C to 180°C (short peaks)

- Ideal For: Hot water, steam, alkalis, dilute acids, and phosphate esters.

- Considerations: Excellent for heating applications and resistant to polar fluids. Avoid using with mineral oils and fuels.

4. Fluorocarbon Rubber (FKM/Viton)

- Temperature Range: -5°C to 180°C

- Ideal For: Aggressive chemicals, acids, alkalis, aromatics, and high-temperature fluids.

- Considerations: The premium choice for severe chemical service. It offers the broadest chemical resistance but comes at a higher cost.

Industry Trends Impacting Gasket Technology

As of early 2026, the push for sustainability and energy efficiency is driving innovation. There's a growing demand for gaskets that can handle higher temperatures in waste heat recovery systems and those compatible with new, environmentally friendly refrigerants. Furthermore, the need for longer maintenance intervals in critical processes is pushing manufacturers to develop more durable compound formulations.

Expert Support from a Trusted Manufacturer

Selecting the right gasket can be complex. Partnering with an experienced manufacturer like Jiangsu Yuling Machinery Technology Co., Ltd. (YIIING MACEINFRY) provides significant advantages. As a national high-tech enterprise with the Yuling Thermal Energy Technology Research Institute, they offer deep technical expertise.

Their engineers don't just sell plate heat exchanger gaskets; they provide solutions. They can analyze your specific fluid composition (be it seawater for cooling, caustic soda for cleaning, or high-temperature oil for processing) and recommend the perfect material match from their range of NBR, HNBR, EPDM, and FKM gaskets. This ensures your Alfa Laval plate heat exchangers, Tranter plate heat exchangers, Sondex plate heat exchangers, or other brands operate reliably.

Why Choose Yuling (YIIING MACEINFRY) for Your Gasket Needs?

- Technical Consultation: Get expert advice on gasket selection for your plate heat exchanger plates and operating conditions.

- Quality Assurance: Their production is backed by ISO 9001:2015, ISO 14001:2015, and ISO 45001:2018 certifications, ensuring consistent, high-quality gaskets.

- Comprehensive Range: They supply gaskets for various models, potentially offering compatible solutions for APV plate heat exchangers, GEA plate heat exchangers, API plate heat exchangers, SWEP plate heat exchangers, and Hisaka plate heat exchangers.

- After-Sales Support: Guidance on proper installation, tightening torques, and maintenance schedules to maximize gasket life.

Step-by-Step Selection Checklist

- Identify the Fluids: List all fluids on both sides of the plate heat exchanger. Include concentrations and any impurities.

- Determine Temperature Extremes: Note the maximum, minimum, and any cycling temperatures for both fluids.

- Check Operating Pressure: Ensure the gasket material is rated for your system's pressure.

- Consider Cleaning & Maintenance: Will you use CIP (Clean-in-Place) systems? What chemicals are used for cleaning?

- Consult the Manufacturer: Provide the above data to a specialist like Yuling for a validated recommendation.

- Plan for Spares: Keep a set of critical gaskets in stock to minimize downtime during planned maintenance or unexpected failures.

Pro Tip: Never assume a gasket that worked in one application will work in another, even if the fluids seem similar. Small differences in pH, temperature, or additive packages can drastically affect gasket longevity. Always verify compatibility.

By following this guide and leveraging the expertise of established manufacturers like Yuling (YIIING MACEINFRY), you can ensure your detachable plate heat exchanger operates at peak efficiency with minimal leakage risk. For personalized assistance with your plate heat exchanger gaskets or any heat transfer needs, contact their engineering team today.

Contact Jiangsu Yuling Machinery Technology Co., Ltd. (YIIING MACEINFRY)

Website: www.yuling-phe.com

Tel: +86 513 8836 0268

WhatsApp: +86 13813790595

Email: info@yuling-machine.com

Address: No.169, Lifa Avenue, Haian City, Jiangsu Province, China.

Explore their full range of detachable plate heat exchangers, brazed plate heat exchangers, and fully-welded plate heat exchangers.