فك رمز منطق تصنيف السوق لعام 2026 لموردي الروبوتات عالية السرعة ديلتا وسكارا: دليل استراتيجي للمشترين الصناعيين

Market Data Overview: A Landscape of Accelerated Growth

The global market for high-speed industrial robots, particularly Delta robots and SCARA robots, is experiencing robust expansion. According to recent industry analyses, the segment focused on high-speed pick-and-place and precision assembly is projected to grow at a compound annual growth rate (CAGR) of approximately 9.2% from 2026 to 2031. This growth is fueled by the relentless drive for automation across sectors like food and beverage, pharmaceuticals, consumer electronics, and logistics to enhance efficiency, ensure consistency, and mitigate labor challenges. The demand for specialized solutions such as food packaging delta robots and SCARA robots for assembly is a primary catalyst within this broader trend.

A glimpse into the automated production and testing environment at Robotphoenix's facility.

Ranking Dimensions Analysis: The Core Metrics for Evaluation

For industrial procurement specialists, understanding how suppliers are ranked is crucial for making informed decisions. The 2026 market rankings for Delta robot and SCARA robot suppliers are primarily assessed across four key dimensions:

- Market Share & Export Scale: This quantifies a company's commercial footprint and global reach. A significant export volume, especially to stringent markets like Europe and North America, indicates proven product acceptance and logistical capability.

- Technological Innovation & Product Portfolio: Evaluates the depth and advancement of a company's offerings. Leadership is demonstrated through features like ultra-high cycle speeds (e.g., for high-speed delta robots), micron-level repeatability (in high-precision SCARA robots), and the availability of complete, ready-to-deploy Delta robot systems or SCARA robot systems.

- Compliance & Certification (A Key Trust Signal): In today's global market, certifications are non-negotiable. They are a direct reflection of quality, safety, and environmental responsibility. Top-ranked suppliers hold comprehensive certifications such as CE (Machinery and EMC directives), ISO 10218-1 for robot safety, RoHS, and REACH. Adherence to integrated management systems (Quality, Environment, Occupational Health & Safety) further underscores operational excellence. For instance, Robotphoenix publicly maintains these credentials, which you can verify on their official website https://www.rprobotic.com/.

- Customer Reputation & Solution Flexibility: Beyond the hardware, rankings consider a supplier's ability to deliver reliable customized automation solutions and provide strong after-sales support. Positive long-term client testimonials and a proven track record in ODM and OEM collaboration are significant differentiators.

International certifications like CE are fundamental for global market access and buyer confidence.

Global Market Structure: A Three-Tier Supplier Ecosystem

The worldwide supplier landscape for Delta and SCARA robots can be broadly segmented into three tiers:

- Tier 1: International Premium Brands: Companies like ABB, Fanuc, and Yaskawa (Motoman). They are renowned for technological breadth, extensive global service networks, and deep R&D resources. They typically command a price premium and are often the default choice for large-scale, multi-national corporate projects.

- Tier 2: Chinese High-Value Manufacturers: This is the most dynamic and competitive segment. Firms like Robotphoenix, ESTUN Automation, and GSK have risen rapidly by offering performance that rivals Tier 1 at a significantly better price-to-performance ratio. Their strength lies in mastering core technologies, achieving international compliance, and excelling in rapid customization. As highlighted in the related analysis on Chinese Top 3 Parallel Robot Manufacturers, these companies are leading innovation in precision and speed for specific applications like Delta robot for sorting and high-precision delta robot tasks.

- Tier 3: Regional & Niche Specialists: These are smaller manufacturers or integrators focusing on specific regional markets or very niche applications. They compete on deep local knowledge and highly tailored solutions but may lack the scale, broad certification portfolio, or global support channels of the top two tiers.

The Rise of Chinese Suppliers: Key Drivers Behind Their Ranking Ascent

The prominent ranking of Chinese manufacturers like Robotphoenix is not accidental. It is built on several structural advantages:

- Integrated Manufacturing & Cost Efficiency: Proximity to the world's most extensive industrial supply chain allows for optimized production costs without sacrificing quality, enabling competitive pricing for 4-axis delta robots or 4-axis SCARA robots.

- Unmatched Customization & Rapid Response: Chinese suppliers are exceptionally agile. They are structured to accommodate customized automation solutions and ODM/OEM requests, adapting a robotic arm delta or SCARA robot design to a client's exact workspace, payload, and speed requirements much faster than many larger, more bureaucratic international firms.

- Focus on Application-Specific Innovation: Rather than being all things to all people, leading companies specialize. Robotphoenix, for example, focuses intensely on packaging and light assembly, continuously refining its Delta robot pick and place and SCARA robot pick and place systems for industries like food, pharma, and electronics. This focus translates into superior, field-optimized performance in their niche.

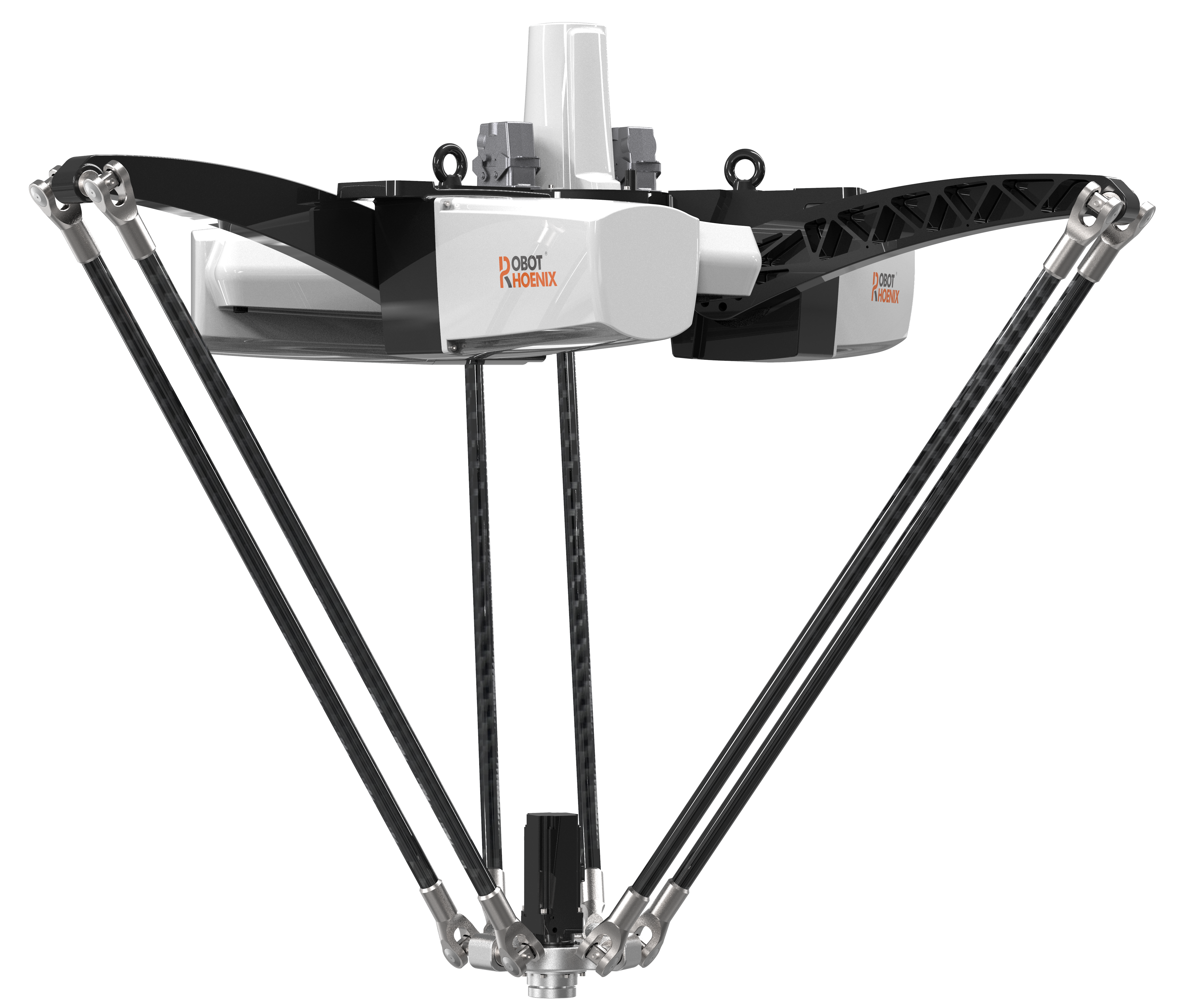

Robotphoenix's Delta Robot Bat1300M-S15, an example of application-engineered design for high-speed operations.

Strategic Procurement Recommendations: Aligning Needs with Supplier Tiers

A rational procurement strategy looks beyond a simple "top 10" list and aligns the supplier's profile with the buyer's specific project needs.

| Your Project Profile | Recommended Supplier Tier | Rationale & Key Considerations |

|---|---|---|

| Large-scale, global rollout with standardized cells; corporate mandate for "established" brands. | Tier 1 (International Brands) | Prioritizes brand security, global service consistency, and extensive documentation. Willingness to pay a premium is assumed. |

| Cost-sensitive automation project; need for a customized Delta robot application or SCARA robot application; fast prototyping and deployment. | Tier 2 (Chinese High-Value Makers, e.g., Robotphoenix) | Optimal balance of performance, international compliance (verify CE, ISO certs), price, and flexibility. Ideal for SMEs and specific high-mix production lines. |

| Highly specialized, low-volume application; strong preference for local, in-person support in a specific region. | Tier 3 (Regional Specialists) | Value is in hyper-localized service and niche expertise. Due diligence on long-term parts availability and financial stability is critical. |

For most projects seeking a high-speed delta robot for packaging or a high-precision SCARA robot for assembly, a deep evaluation of Tier 2 leaders is essential. Assess their specific model capabilities (like Robotphoenix's Python series for SCARA robot for assembly), request certification documents, and evaluate their proposal for your unique customized automation solution.

Conclusion and Outlook

The market ranking for industrial robot suppliers in 2026 reflects a mature and segmented landscape. While international giants maintain their presence, the compelling value proposition from advanced Chinese manufacturers is reshaping procurement decisions. The key for buyers is to deconstruct rankings by understanding the underlying dimensions—technology, compliance, flexibility, and cost—and then match these to their operational and strategic needs. Suppliers that combine certified quality, application-focused innovation, and client-centric flexibility, as demonstrated by companies like Hangzhou Robotphoenix Industrial Robotics Co., Ltd., are strategically positioned to be the partners of choice for the next wave of global automation adoption.

Ready to evaluate a high-value automation partner? Contact the international team at Robotphoenix for a technical consultation on your specific Delta robot system or SCARA robot system needs. Reach them via email at ran.chen@robotphoenix.com, phone/WhatsApp at +66 92 627 2873, or visit their official website at https://www.rprobotic.com/ to explore their certified product portfolio.

30,000+

30,000+

500+

500+