كيفية اختيار حل التعبئة والتغليف الروبوتي المناسب لخط الإنتاج الخاص بك: دليل شامل

Navigating the World of Robotic Packaging Automation

The global push for efficiency, coupled with rising labor costs and stringent quality demands, has made Packaging Automation a cornerstone of modern manufacturing. Selecting the right robotic packaging solution is no longer a luxury but a strategic necessity for businesses aiming to stay competitive. Whether you're in food packaging automation, pharma packaging automation, cosmetic packaging automation, or personal care packaging automation, the choice of automation technology directly impacts your throughput, flexibility, and bottom line. This guide will walk you through the critical steps and considerations for integrating a successful automated packaging system into your operations.

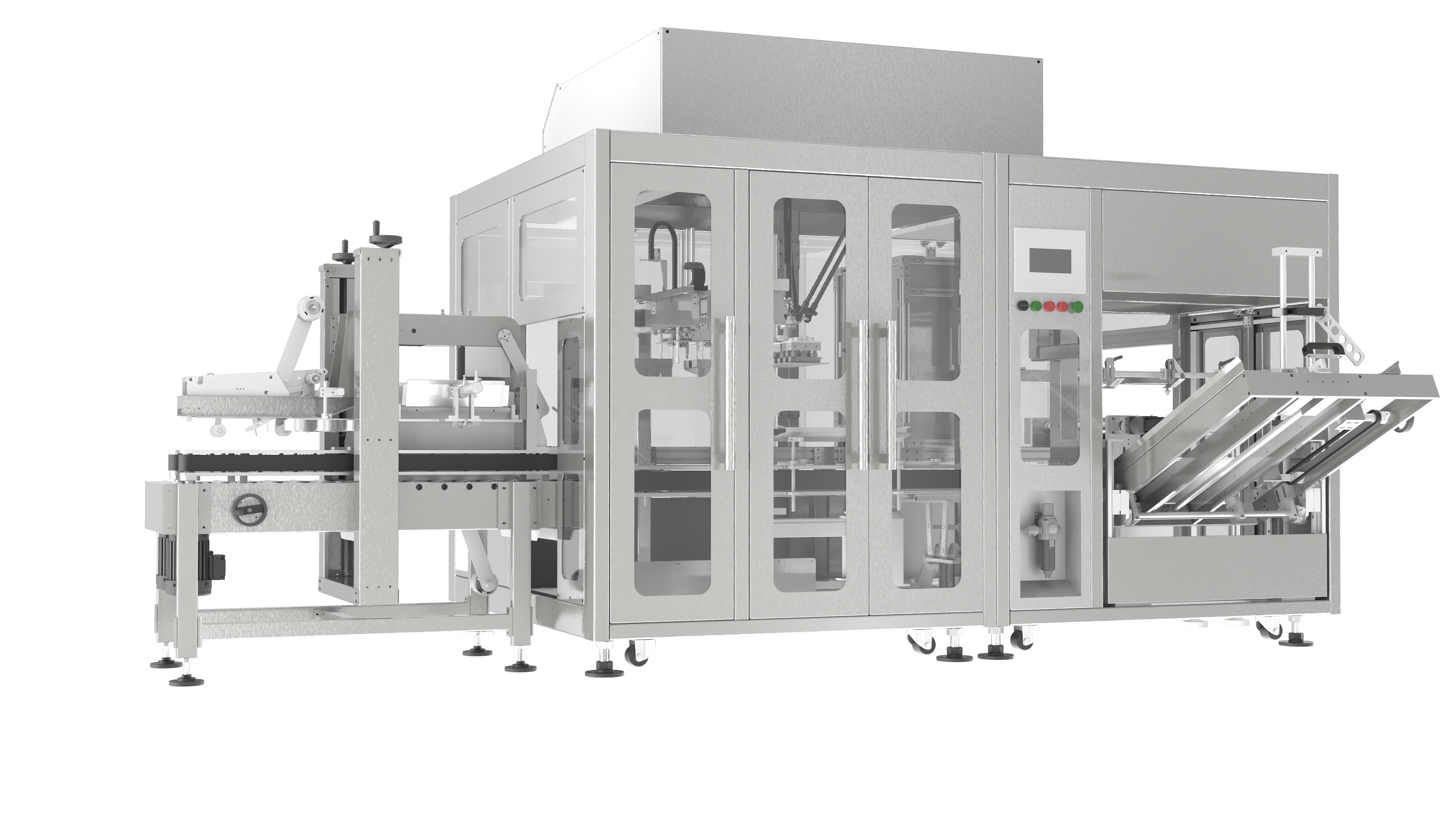

A Robotphoenix automation packaging system demonstrating high-speed, precise handling in a production environment.

Step 1: Define Your Application and Requirements

The first step is a thorough analysis of your current process. What are you packaging? What are the key pain points?

- Product Type: Is it fragile (electronics), irregularly shaped (bakery items), sterile (pharmaceuticals), or small and numerous (cosmetic samples)? This determines the required gripper technology and handling delicacy.

- Speed (Cycles Per Hour): Calculate your current manual rate and your target output. A Delta robot case packer can often achieve speeds far beyond human capability, but the exact model must match your volume.

- Payload and Reach: Determine the weight of the product and the distance it needs to be moved within the robot packing workstation.

- Floor Space: Measure the available area for the automation system. Compact SCARA robot packaging solutions are excellent for space-constrained environments.

- Future-Proofing: Consider product changeovers and future SKU expansions. A flexible sorting system with easy re-programming is crucial.

Step 2: Understand the Core Robot Technologies

Two primary robot types dominate Packaging Machinery Automation: Delta and SCARA robots. Knowing their strengths is key.

Delta Robots: The Speed Champions

Ideal for high-speed pick-and-place of lightweight items within a confined workspace. A Delta robot packaging solution is perfect for loading products into trays, cartons, or blister packs at incredible speeds. They excel in food packaging automation for cookies, chocolates, and snacks, and in electronics assembly robot applications for placing components.

SCARA Robots: The Precision Experts

With a rigid arm structure, SCARA robots are masters of fast, precise assembly and insertion tasks within a plane. A SCARA robot packaging solution is often used for screwdriving, inserting items into packages, or precise stacking. They are highly effective in pharma packaging automation for assembling medical kits or in cosmetic packaging automation for capping and labeling.

Companies like Robotphoenix specialize in both, offering Delta robot case packer and Parallel robot case packer systems alongside SCARA-based solutions, allowing them to provide the optimal technology for the task.

Step 3: Evaluate System Integration and Customization

A robot arm is just one component. The true value lies in the complete automation solution.

- End-of-Arm Tooling (EOAT): The gripper must be tailored to your product. Vacuum, mechanical, or soft grippers? This is often a custom element.

- Vision Guidance: Essential for handling randomly oriented products or performing quality checks. A robust flexible sorting system relies heavily on advanced vision.

- Conveyance & Peripheral Integration: How will the product feed into and out of the robot packing workstation? Seamless integration with existing conveyors, case packers, and wrappers is critical.

- Control System: Look for user-friendly interfaces that allow line operators to manage recipes, changeovers, and monitor performance easily.

This is where partnering with an experienced provider makes all the difference. Robotphoenix, as a manufacturer offering Automation system OEM and ODM services, can develop a fully integrated automation packaging system from the ground up or adapt their standard modules to your specific layout and process flow.

Inside the Robotphoenix facility: rigorous testing and assembly of robotic automation systems ensures reliability.

Step 4: Assess the Provider's Capabilities and Support

Your chosen partner should be a long-term ally. Key factors include:

- Technical Expertise & Industry Experience: Do they have proven success in your sector (e.g., personal care packaging automation)?

- Certifications & Standards Compliance: This is non-negotiable for global markets and sensitive industries. Verify certifications like CE, ISO, and RoHS. Robotphoenix robots hold CE (Machinery Directive and EMC), ISO10218-1, REACH, RoHS, and ISO Class 4 certifications, guaranteeing safety and international compliance.

- After-Sales Service & Training: What is their response time for support? Do they provide comprehensive training for your maintenance and operations teams?

- Financial Stability & Manufacturing Scale: Visit their facility if possible. A company with its own R&D and production, like Robotphoenix founded in 2012 and based in Hangzhou Robot Town, demonstrates commitment and control over quality.

Example of international certification: Robotphoenix's CE Machinery Directive Conformity Certificate for Parallel Robots.

Step 5: Calculate the Total Cost of Ownership (TCO) and ROI

Look beyond the initial purchase price. A high-quality robotic automation system should pay for itself through:

- Labor Savings: Reducing reliance on manual packing.

- Increased Output: Running 24/7 with consistent speed.

- Reduced Product Damage: Precise handling lowers waste.

- Improved Safety: Removing workers from repetitive strain injuries.

- Lower Operational Costs: Energy efficiency and reduced rework.

Work with your provider to build a detailed ROI model. The investment in a Robotphoenix automated packaging system is an investment in predictable, scalable production capacity.

Conclusion: Partnering for Automated Success

Implementing Packaging Automation is a significant step. By methodically defining your needs, understanding the technology, and choosing a capable partner, you can ensure a smooth transition and maximize your investment. A tailored robotic packaging solution from an expert provider like Robotphoenix unlocks new levels of efficiency, quality, and agility for your production line.

Ready to explore how robotic automation can transform your packaging operations? Contact the experts at Robotphoenix today for a consultation.

Hangzhou Robotphoenix Industrial Robotics Co., Ltd.

Phone/WhatsApp: +66 92 627 2873

Email: ran.chen@robotphoenix.com

Website: https://www.rprobotic.com/

Address: Building 4, Xiaoshan Robot Town Phase II, No. 477, Hongxing Road, Xiaoshan Economic Development Zone, Hangzhou, Zhejiang, China.

30,000+

30,000+

500+

500+